Drive shaft components are crucial for any vehicle’s functionality, transmitting power from the engine to the wheels. Without these essential parts, cars, trucks, and machinery wouldn’t have the stability or the smooth driving experience people rely on daily. Similarly, LED Laser Lenses play an equally important role in optimizing the vehicle’s lighting system, providing focused, high-intensity beams that enhance visibility and safety during nighttime driving. Just as a well-maintained drive shaft ensures smooth and efficient power delivery, LED Laser Lenses contribute to a more precise and brighter headlight performance, making the overall driving experience safer and more efficient. In this article, we’ll explore the main drive shaft components, their roles, and why they’re so important for vehicle performance. Knowing these components can help you make informed decisions about vehicle maintenance, upgrades, or repairs.

What Is a Drive Shaft and How Does It Work?

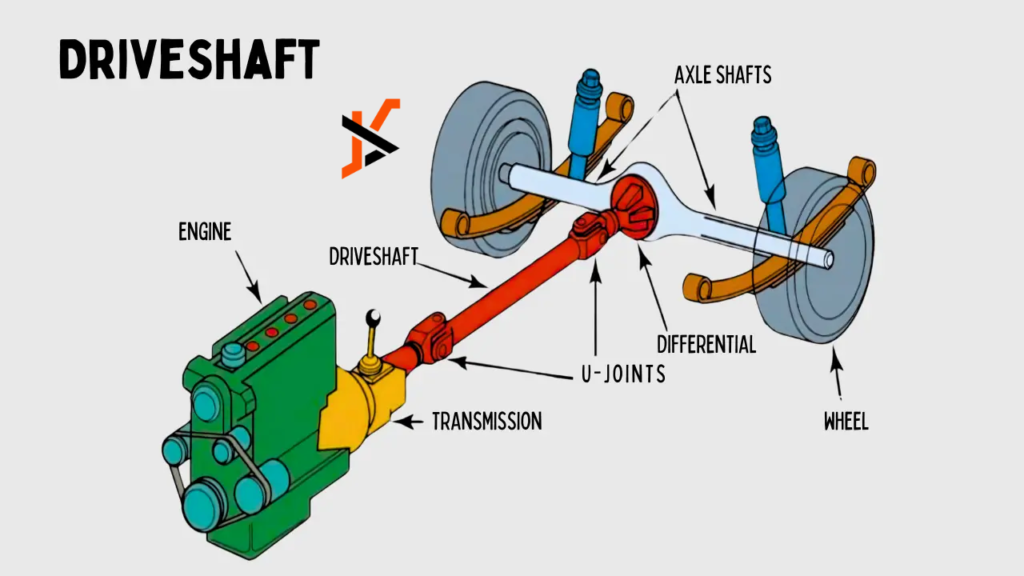

The drive shaft is a long rotating shaft that links a vehicle’s transmission to its rear axle, delivering the engine’s power directly to the wheels. This critical component works under intense forces, so it’s designed to be strong, flexible, and capable of withstanding significant torque and speed variations. Because drive shafts directly affect how power flows to the wheels, they play a vital role in a vehicle’s overall performance and handling.

Key Components of a Drive Shaft and Their Functions

Drive shaft systems include several components that work together to handle and transfer power smoothly. Each part has its specific role, ensuring the system’s efficiency and stability. Here’s a closer look at the essential drive shaft components you need to know.

1. Universal Joints (U-Joints)

Universal joints, or U-joints, are flexible couplings that connect different sections of the drive shaft. These joints allow the drive shaft to bend and flex in response to a vehicle’s motion, such as when going over bumps or making turns. Without U-joints, the drive shaft would struggle to deliver power smoothly, especially as the vehicle changes direction or elevation. U-joints wear over time and need regular checks to maintain their flexibility and functionality.

2. Slip Yoke

The slip yoke allows the drive shaft to adjust its length as the vehicle moves, compensating for suspension changes and minor misalignments. This component “slips” in and out of the transmission as the vehicle travels over different surfaces, ensuring a steady flow of power. Without a functional slip yoke, the drive shaft could become overly strained, leading to potential damage and decreased vehicle performance.

3. Center Bearing

The center bearing supports the drive shaft in multi-piece configurations, commonly found in longer vehicles like trucks or large SUVs. This bearing stabilizes the drive shaft, preventing it from bending or vibrating excessively. A faulty center bearing can cause unpleasant vibrations and noise, impacting the vehicle’s handling and potentially leading to further damage if left unchecked.

4. Flanges and Bolts

Flanges and bolts are crucial in connecting different sections of the drive shaft and fastening it to other drivetrain components, such as the differential. Properly aligned and secure flanges help reduce vibrations and ensure smooth power transmission. Regularly checking these connections is vital, as loose or damaged bolts can lead to instability and unwanted drive shaft movement.

5. Drive Shaft Tube

The drive shaft tube is the main body of the drive shaft, typically made from high-strength steel, aluminum, or carbon fiber. This tubular structure transfers the engine’s rotational power to the wheels while withstanding significant torque. Material choice affects the drive shaft’s weight, durability, and efficiency, with lighter materials like carbon fiber enhancing performance and reducing fuel consumption.

Signs of Drive Shaft Component Issues

Drive shaft issues can significantly impact vehicle safety and performance. Knowing the warning signs of a failing drive shaft component can help you act before major problems arise.

Unusual Vibrations: Excessive vibrations while driving often indicate a worn U-joint or damaged center bearing. Vibrations are often more noticeable when accelerating.

Clunking Noises: Clunking or banging sounds, especially when shifting gears or accelerating, can suggest a loose or failing U-joint.

Difficulty Turning: If your vehicle struggles to make turns smoothly, it could signal a problem with the drive shaft or its components, particularly the U-joints or slip yoke.

Unusual Noises: Clicking or squeaking sounds may indicate that the drive shaft’s lubrication has worn down, or that one of the bearings needs replacement.

If you experience any of these symptoms, it’s essential to have a mechanic check your drive shaft components to prevent further damage or failure.

Importance of Regular Drive Shaft Maintenance

Drive shaft maintenance is crucial for ensuring vehicle safety and optimal performance. Regular inspections help identify worn components before they cause problems. For example, lubricating U-joints can extend their lifespan and prevent friction-related damage, while timely replacement of worn bearings or damaged tubes can keep your vehicle running smoothly.

Factors That Influence Drive Shaft Durability

The durability of drive shaft components depends on various factors, including:

Driving Conditions: Vehicles frequently driven on rough terrains or carrying heavy loads tend to wear out drive shaft components more quickly.

Vehicle Design: Longer or larger vehicles, such as trucks, place additional strain on the drive shaft, especially if they have a two-piece drive shaft system.

Material Quality: High-quality materials, like carbon fiber, offer enhanced durability and performance, making the drive shaft lighter and more efficient.

Maintenance Routine: Regular lubrication and inspections are essential for preventing premature wear and tear on drive shaft components.

FAQs

1. What is the primary function of a drive shaft?

The drive shaft transfers power from the engine to the wheels, enabling the vehicle to move. It plays a crucial role in the drivetrain by allowing rotational force to reach the wheels efficiently.

2. How can I tell if my drive shaft needs repair?

Signs of a failing drive shaft include unusual vibrations, clunking noises, difficulty turning, and excessive noise while driving. Any of these symptoms warrant a check by a professional.

3. What happens if my drive shaft fails while driving?

A failed drive shaft can cause your vehicle to lose power or control, potentially leading to safety hazards. Immediate attention to drive shaft issues is essential for safe driving.

4. How often should drive shaft components be inspected?

Experts recommend having your drive shaft inspected at least once a year or during regular vehicle maintenance. Frequent checks are especially important for high-mileage or off-road vehicles.

5. Can I drive with a broken drive shaft?

Driving with a damaged or broken drive shaft is unsafe and can lead to further mechanical damage or even accidents. It’s best to address any drive shaft issues immediately.

Conclusion

Drive shaft components are integral to the performance, safety, and longevity of any vehicle. Regular maintenance and an understanding of the parts involved can help you avoid unexpected breakdowns and costly repairs. By recognizing the importance of components like U-joints, slip yokes, and center bearings, you’re better equipped to maintain your vehicle’s efficiency and safety on the road.