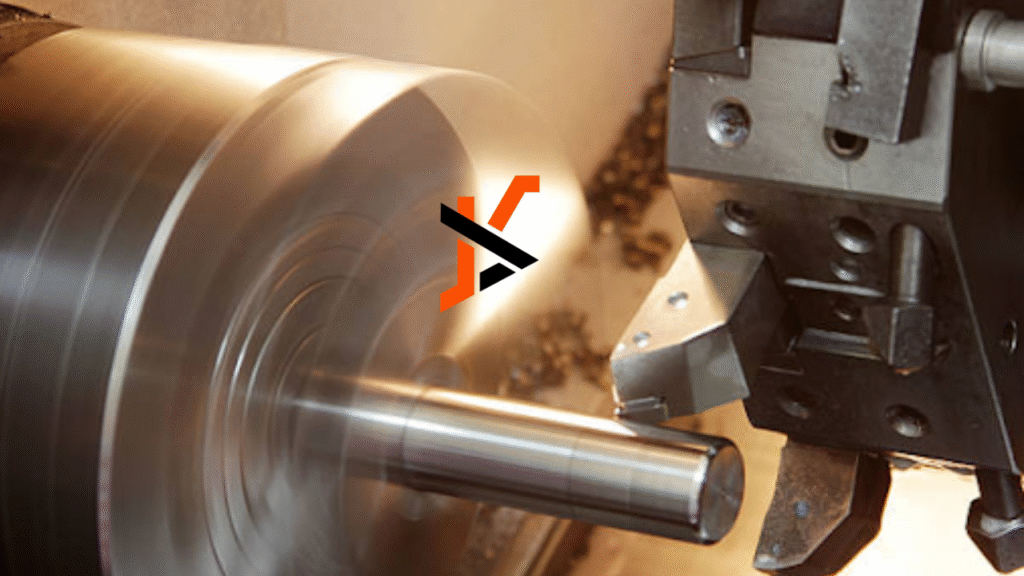

Over the past few years, China CNC turning manufacturers have been participating in international supply chains. The CNC machining prototype manufacturers’ capabilities to create meticulously crafted pieces in bulk has enabled businesses around the world to increase operational efficiency, cut expenses, and enhance product design. With the growing demand for high quality and these the manufacturers are able to provide, China is assuming a greater role in the fulfillment of different requirements of B2B businesses.

China has become one of the leading countries in manufacturing medical equipment, electronics, aerospace and automotive products. The advancements in CNC turning technology allows CNC turning manufacturers China to deliver products to all B2B companies with varying needs. In this article, I will explain how these manufacturers shape the supply chains of the world and how they affect the operation of firms in the globalized economy.

How CNC Turning Manufacturers in China Contribute to the Global Supply Chain

China is one of the world’s leading CNC machining prototype manufacturers, with a highly developed infrastructure that supports large-scale production. CNC turning manufacturers China specialize in creating high-precision parts essential to numerous industries, such as aerospace, automotive, and medical devices. Their expertise and technological capabilities allow them to deliver complex, precision parts that are critical to the success of these industries.

- Cost Efficiency: China offers some of the most competitive manufacturing costs in the world. By partnering with CNC machining prototype manufacturers in China, companies can reduce production costs significantly without sacrificing quality. This has allowed many businesses to lower their overall operational expenses and increase profitability, helping companies remain competitive in the global marketplace.

- Large Production Capacity: Chinese manufacturers have the capability to produce large volumes of CNC turning parts quickly. This is particularly beneficial for industries with high-demand products, such as the automotive sector, where millions of components are needed every year. With advanced CNC turning technology, manufacturers can meet tight deadlines and ensure continuous production without disruptions, enabling businesses to stay on track with customer orders.

- Advanced Technology: CNC machining prototype manufacturers in China have access to the latest CNC technology, which allows for the production of complex parts with tight tolerances. This technology is crucial for industries that require high precision, such as aerospace and medical devices. With these capabilities, Chinese CNC turning manufacturers can support various industries with high-quality, reliable components that meet the most stringent standards.

By collaborating with a CNC machining prototype manufacturer, businesses can take advantage of China’s advanced manufacturing capabilities, ensuring high-quality parts that contribute to an efficient and effective global supply chain.

Driving Innovation Through Rapid Prototyping Capabilities

One of the best benefits that China CNC machining prototype manufacturers have to offer is their capability to foster innovation with the use of rapid prototyping. Modern multi-axis CNC turning technologies permit manufacturers to easily and rapidly transform design ideas into actual testable components. This type of prototyping helps firms refine product designs prior to going into full scale production which leads to reduced costs and time in the product development cycles. Rapid Prototyping is something that allows companies to develop products efficiently.

For B2B enterprises in aviation, automotive, and medical device sectors, speed to market is vital. Chinese manufacturers who make turn prototypes help businesses achieve their goals with rapid prototyping. This enables companies to test functionality and alter the product to meet the required specifications before moving into larger production runs. By this approach, the company can build a more sophisticated product before its introduction into the market, which drastically reduces the chances of expensive design flaws.

Besides assisting with product refinement, Chinese manufacturers also give DFM – design-for-manufacturing assistance. This type of assistance allows companies to tackle certain issues regarding the methods of production less expensively. With rapid prototyping and fierce competition on the rise, being able to dynamically adapt to new challenges gives a solid edge to just about every firm.

The Role of CNC Turning in Diverse Industrial Applications

Turning manufacturers in China have become a highly reliable source for a large number of industries that require high accuracy components and components for numerous applications. Due to the versatility of CNC turning, it is often employed in aerospace industries, automotive, electronics, and even medical devices. As businesses require parts of a certain ruggedness, reliability, and superior quality, CNC turning is becoming vital in providing solutions to these needs.

- Aerospace: Engine parts, actuator components, and landing gear parts are some of the components that require very high CNC turning, in terms of precision and reliability, complexity, and integration. The turning parts provided by CNC turners in China are imperative to the safety and performance standards that need to be adhered to in aerospace applications.

- Medical Devices: Modern bone screws, custom implants, precision medical syringes, and CNC surgical instruments are examples of components produced using CNC turning technology. These parts need to be rigorously manufactured to meet the specified health US and industry ISO standards so that they can positively impact the medical market. Chinese manufacturers ensure that these results go to the medical field because they are much needed and very important for patients.

- Automotive: With the ability to produce complex shapes and features with great accuracy, CNC turning has the capability to create gears, components of valves, crankshafts and a lot more. Together with turning parts suppliers from China, the automotive sector is greatly aided as there are more dependable, economical, and high quality components that are needed for the proper operation of automobiles.

- Electronics: Small parts such as connectors and heat sinks that are necessary for consumer electronics can be produced through CNC turning. With the advancement in technology, the shrinking of parts and increased intricacy of components requires CNC turning for the necessary level accuracy in keeping up with the changing market demands.

This broad industrial applicability shows how CNC turning manufacturers in China support the global supply chain by providing solutions that are customized to meet the specifications of various industries

Choosing the Right CNC Turning Manufacturer in China

When bringing a CNC turning manufacturer into the supply chain, there are some important criteria that need to be checked to make sure you’re working with the right supplier. Selecting a CNC machining service factory with highly misplaced capabilities could undermine the effectiveness and success of production.

- CNC Turning Experience: Find a manufacturer who can perform CNC turning and understands complex geometries and high precision needs. The CNC turning manufacturer should also provide multi axis machines to accommodate more complex designs of parts.

- Company Credentials: Any respectable CNC prototype machining services provider should be ISO 9001 certified and have industry accepted quality controls. This guarantees that each part meets tolerances and specifications which is crucial for the aerospace, automotive, and medical devices industries.

- Adaptability: Whether you are looking for low volume production for prototyping or high turnarounds for mass production, make sure the manufactuer can provide for both. A great CNC turning manufacturer is one who can respond positively to changes in demand or supply for your production volume.

- Customer Communication and Logistics: Having seamless interactions as well as clear logistics greatly enhances operational efficiency. Make sure that the CNC machining prototype manufacturer you select has an established communication system that can provide timely updates on production and shipment progress.

Conclusion

The CNC turning manufacturers from China have altered global supply chains profoundly by integrating precision, customization, and cost-efficiency into CNC machining business services. Not just CNC machining prototype services, such manufacturers from China serve as critical suppliers and also play an important role in marketing new ideas across multiple industries.

B2B clients purchasing from Chinese manufacturers can maximize the benefits of working with a reliable CNC machining service factory which facilitates Chinese produced products into a more cost effective chain. While this is done quality optimization is simultaneously activated. China’s place in the evolution of global manufacturing is assured and working with China ensures that global supply chains become more responsive, flexible, and efficient.