Electric vehicles (EVs) are reshaping the transportation landscape with their promise of zero tailpipe emissions, superior efficiency, and reduced dependence on fossil fuels. Central to this transformation are innovations in drivetrain architecture, and among the most compelling is the integration of Hub Motors—motors housed directly within the wheel assembly. This design paradigm shift offers simplified mechanical systems, precise torque control, and packaging flexibility that can redefine vehicle dynamics, cost structures, and user experiences.

Historical Evolution of In-Wheel Drive Technologies

The notion of situating propulsion units within the wheel hub dates back to the dawn of automotive history. In 1900, Ferdinand Porsche showcased the Lohner–Porsche electric hybrid, featuring wheel-mounted motors on a four-wheel chassis—a groundbreaking demonstration of direct-wheel drive. However, early limitations in materials, insulation, and power electronics relegated in-wheel concepts to experimental prototypes for much of the 20th century.

Fundamentals of Hub Motor Design

Core Components

A hub motor comprises:

- Stator: Laminated steel core with copper windings responsible for generating electromagnetic fields.

- Rotor: Permanent magnet or wound rotor that interacts with the stator’s field to produce torque.

- Bearings and Seals: Robust units to handle road shocks, vibrations, and environmental ingress.

- Power Electronics: Inverter modules (IGBT or SiC MOSFET-based) that convert DC battery energy to three-phase AC for motor operation.

- Cooling Mechanisms: Channels or embedded liquid circuits to dissipate heat from the stator and power electronics.

Operating Principles

When the controller inputs current into windings, a rotating magnetic field forms, exerting torque on the rotor’s magnets. By modulating switching frequencies and phase angles via pulse-width modulation (PWM), the system achieves precise speed and torque control. Regenerative braking reverses this process—kinetic energy returns to the battery through the inverter, boosting overall system efficiency.

Advantages of Hub Motors

Mechanical Simplification

By integrating motor, inverter, and sometimes gear reduction directly in the wheel, hub motors eliminate the need for central transmissions, driveshafts, and differentials. This reduces the number of moving parts, lowers mechanical losses, and can lead to quieter, more reliable systems.

Enhanced Torque Vectoring and Handling

Individual control over each wheel’s torque enables dynamic torque vectoring—applying more torque to outer wheels during cornering, improving grip, stability, and handling precision. Real-world results have shown up to 20% improvement in cornering speeds under test conditions.

Packaging and Space Utilization

Without bulky mechanical linkages, automakers can reimagine chassis layouts. Vehicles gain additional cabin space, flat floors for enhanced interior design, or larger battery packs without sacrificing passenger or cargo volume.

Regenerative Braking Efficiency

Independent regenerative braking at each wheel allows for optimized energy recovery strategies tailored to load and slip conditions, pushing regenerative efficiency above 70% in controlled testing environments.

Technical Challenges and Mitigation Strategies

Unsprung Mass Implications

Placing motors in wheels increases unsprung mass, impacting ride comfort and handling. Mitigation approaches include:

- Developing lightweight motor components using advanced alloys.

- Integrating active suspension systems that counteract increased unsprung mass.

- Employing adaptive damping technologies that adjust in real time.

Thermal Management in Confined Spaces

Hub motors face heat buildup from both motor losses and inverter switching. Solutions:

- Liquid cooling channels are integrated within the rotor/stator interface.

- High-conductivity composites for heat spreading.

- Thermal interface materials optimized for thin cross-sections.

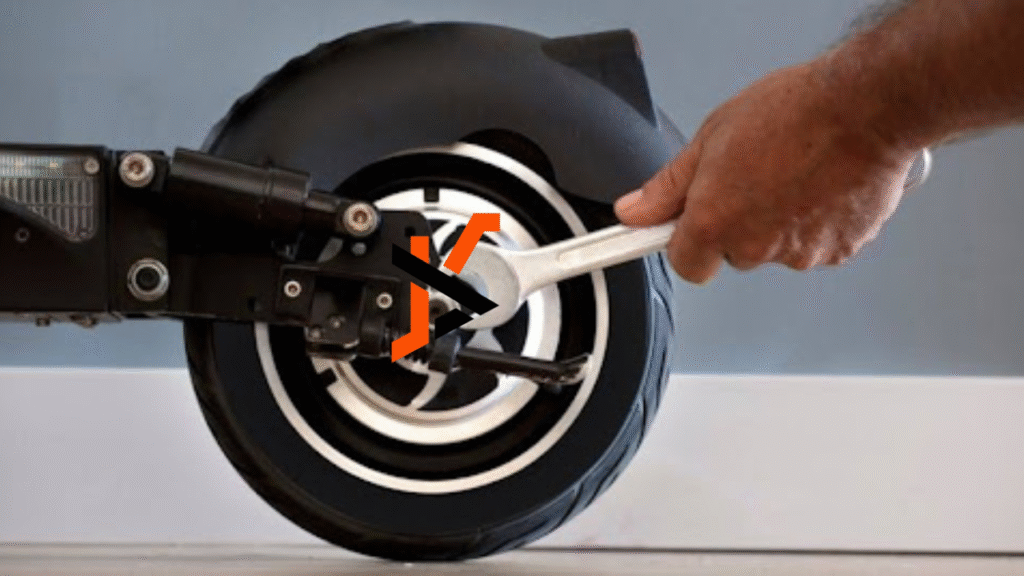

Durability and Robustness

Exposure to road debris, water, and shocks requires:

- High-IP-rated enclosures.

- Sealed connectors and corrosion-resistant materials.

- Reinforced bearings and impact-absorbing mounts.

Cost Considerations

Hub motors currently command a premium due to:

- Specialized manufacturing processes.

- Integration of power electronics in hostile environments.

- Smaller production volumes than central motors.

Design Variations and Innovations

Gearless (Direct Drive) Hub Motors

Simplest form factor—high torque at low speeds without additional gear reductions, but results in larger diameters for high-power applications. For example, a 1000w gearless hub motor has a rated speed of 25-55 km/h, but can reach a high torque of 45-55 N.m.

Geared Hub Motors

Incorporate planetary or spur gearsets to multiply torque and reduce the size of the electric machine. While adding complexity, they achieve higher wheel torque with smaller motor assemblies.

Hybrid Approaches

Combine in-board central motor assistance for high speeds with hub motors for low-speed torque and maneuvering, offering balanced performance across driving conditions.

Integrated Power Electronics

Emerging designs embed inverters and control units directly within the hub, minimizing cable runs and improving response times, but pose thermal and packaging challenges.

Control Systems and Software Algorithms

Torque Control Strategies

Field-oriented control (FOC) remains the standard, enabling precise electromagnetic vector alignment for smooth torque delivery. Advanced model-predictive controls (MPC) offer predictive responses to dynamic load changes.

Regenerative Braking Algorithms

Multi-wheel coordination algorithms optimize braking force distribution based on wheel slip, battery state-of-charge, and traction conditions to maximize energy recovery while maintaining steering stability.

Vehicle Stability and Yaw Control

Real-time torque adjustments counter understeer/oversteer, leveraging individual hub motor agility to maintain intended yaw rates without traditional stability control systems.

Diagnostics and Fault Management

Embedded sensors and self-diagnostic routines detect anomalies in torque output, temperature spikes, or electrical faults, triggering safe-mode operation and driver alerts.

Sector-Specific Applications

Two-Wheelers and E-Bikes

E-bike hub motors dominate the EV cycling market, offering quiet, efficient propulsion with pedal-assist modes. Many manufacturers have sold millions of units globally.

Passenger Cars

Concept and prototype vehicles from major OEMs—including Renault’s Twizy and Aptera solar EV—demonstrate hub motor viability, showcasing flat-floor designs and agile handling.

Commercial Vehicles and Buses

City buses equipped with in-wheel motors reduce drivetrain maintenance, improve regenerative efficiency in stop-and-go traffic, and enable modular electric axle replacements.

Specialty Vehicles (Robotics, Industrial)

AGVs (Automated Guided Vehicles) and robotics platforms leverage hub motors for precise motion control in warehouses and manufacturing floors.

Manufacturing, Materials, and Supply Chain

Rare Earth and Magnetic Materials

High-performance permanent magnets (neodymium-iron-boron) drive torque density but face supply concentration risks. Research into ferrite alternatives and recycling is ongoing.

Lightweight Alloys and Composites

Aluminum and magnesium alloys reduce rotor/inverter housing weight. Composite encapsulations provide vibration damping and environmental sealing.

Coil Winding and Insulation Technologies

Automated Megasonic winding systems improve coil density and reduce insulation voids. High-temperature polymer insulation supports elevated operating temperatures.

Supply Chain Risks and Localization

Geopolitical tensions can disrupt the rare earth supply. Localized manufacturing and magnet recycling partnerships mitigate risks.

Market Trends and Economic Impact

Market Size and Growth Projections

The global hub motor market is projected to grow at a CAGR of 10–12% from 2024 to 2030, driven by electric two-wheeler expansion in Asia and emerging light EV segments in Western markets.

Key Industry Players

Protean Electric, Elaphe, YASA, EVATEC, and domestic OEM divisions lead hub motor development. Partnerships with Tier-1 suppliers (Bosch, Continental) accelerate commercialization.

Regional Adoption Patterns

China’s e-bike market accounts for over 70% of global sales, with hub motors standard across price tiers. Europe’s micro-mobility operators deploy hub-driven e-scooters in urban fleets. North America trials passenger EVs with hub motors in pilot programs.

Total Cost of Ownership Considerations

While per-unit costs are higher, savings from simplified maintenance, increased energy recovery, and modular replacement parts can offset initial premiums over vehicle lifetimes.

Sustainability and Lifecycle Analysis

Energy Efficiency Gains

Reducing drivetrain losses and maximizing regenerative braking yields 5–8% overall vehicle energy efficiency improvements.

Material Recyclability

Modular hub units facilitate end-of-life disassembly. Magnet and copper coil recycling recover critical materials.

End-of-Life Treatment

Standardized take-back programs ensure hub motor cores and power electronics are processed for material recovery.

Circular Economy Perspectives

Design for disassembly, remanufacturing, and parts refurbishment extends component lifespans and reduces environmental impact.

Future Outlook and Emerging Innovations

Active Suspension Integration

Combining hub motors with electromagnetic suspension could neutralize unsprung mass effects, delivering both propulsion and ride comfort benefits.

Wireless In-Wheel Charging

Pilot projects embed charging coils in roadways to top up hub-powered EVs in motion, reducing range anxiety and infrastructure strain.

Advanced Materials and Manufacturing Techniques

Graphene-enhanced windings and 3D-printed cooling channels promise higher performance at lower weight.

Autonomous Driving Synergies

Independent wheel control dovetails with autonomous vehicle algorithms, enabling precise motion control for self-driving platforms.

Conclusion

Hub Motors represent a transformative force in EV design, marrying simplified mechanical systems with advanced control capabilities. From two-wheelers to concept passenger cars and commercial fleets, hub motors offer compelling advantages in packaging, handling, and efficiency. While challenges, such as unsprung mass and thermal management, remain, ongoing innovations in materials, cooling strategies, and integrated electronics are closing the gap. As regulatory frameworks, standardization efforts, and market adoption accelerate, hub motor technology is poised to play a pivotal role in the future of sustainable mobility.

Frequently Asked Questions

What are Hub Motors?

Hub Motors are electric drive units positioned within the wheel hub, eliminating traditional drivetrain components and enabling individual wheel control.

How do hub motors enhance vehicle performance?

By enabling torque vectoring, reducing mechanical losses, and optimizing regenerative braking at each wheel, hub motors improve handling, efficiency, and energy recovery.

What are the main drawbacks of hub motors?

The primary challenges include increased unsprung mass, complex thermal management, robust sealing requirements, and higher initial costs compared to central drivetrains.

Which vehicle types benefit most from hub motor integration?

Two-wheelers and e-bikes currently see the highest adoption. Pilot programs in passenger cars and urban buses are demonstrating the viability of hub motors in larger platforms.