Material testing laboratories play a key role in verifying the strength, durability, and compliance of metals, polymers, rubbers, and composite materials across nearly every industrial sector. However, accurate testing results alone are not enough. In 2025, laboratories must also prove that their procedures, equipment, and reporting methods follow recognized industry standards.

Compliance with these standards is necessary to maintain credibility, meet client and regulatory requirements, and provide valid and traceable test outcomes. Without it, a laboratory’s data may be rejected by certifying bodies, leading to delays, lost contracts, or legal complications.

In this article, we examine the top 5 industry standards that material testing laboratories must comply with by 2025. These are specific, widely adopted standards that define how tests must be performed, how results must be documented, and how laboratories must operate to remain competitive and trusted in global markets.

Standards That Define Modern Compliance in 2025

While there are dozens of standards available depending on material type and industry, a few remain central to global compliance. These core standards define how tests should be performed, how equipment must operate, and how labs should manage accuracy, calibration, and reporting.

Below are five of the most important and widely used standards that material testing labs must comply with in 2025. These standards apply to various sectors, including aerospace, automotive, defense, construction, and manufacturing, and represent the minimum baseline for trusted and legally recognized testing.

1. ISO/IEC 17025 – General Requirements for the Competence of Testing and Calibration Laboratories

As a starting point, we will refer to ISO/IEC 17025 – the international standard that specifies the general requirements for laboratory competence, impartiality, and consistency. It applies to all organizations that perform testing, regardless of size or industry.

This standard covers technical aspects such as method validation, measurement uncertainty, traceability, and calibration. It also sets strict requirements for equipment maintenance, personnel qualifications, and documentation. Laboratories accredited to ISO/IEC 17025 must demonstrate that their test results are accurate, repeatable, and traceable to international measurement systems.

For material testing labs, this standard is a necessity. It is often a mandatory requirement in supply chains and is frequently audited by regulatory bodies and clients in the aerospace, automotive, and defense sectors.

2. ASTM E8/E8M – Standard Test Methods for Tension Testing of Metallic Materials

ASTM E8/E8M is the commonly used standard for metal tensile testing. It provides detailed instructions for preparing specimens, conducting tests, and reporting results for metallic materials under uniaxial tensile loading at room temperature.

The standard defines parameters such as gauge length, crosshead speed, extensometer placement, and data interpretation. It is commonly used to determine yield strength, ultimate tensile strength, and elongation values critical to product design, quality control, and certification.

This standard is required for mechanical testing in industries such as structural steel, aerospace alloys, and automotive components. Test results are only valid when performed using calibrated machines and properly machined specimens according to ASTM E8/E8M procedures.

3. ISO 6892-1 – Metallic Materials – Tensile Testing at Room Temperature

Next, we have ISO 6892-1, which is the international counterpart to ASTM E8/E8M. It standardizes tensile testing procedures for metallic materials across Europe and other international markets. The standard is part of the ISO 6892 series, which also includes testing at elevated and low temperatures.

ISO 6892-1 specifies two testing methods: strain rate control (Method A) and stress rate control (Method B). The standard specifies equipment accuracy, extensometer requirements, and data processing rules to ensure consistent test results globally.

Material testing labs that serve international clients or are involved in exporting materials must comply with ISO 6892-1. Failure to follow it can lead to the rejection of data in markets that require ISO-aligned procedures.

4. ASTM D412 – Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers – Tension

ASTM D412 outlines methods for testing rubber and elastomeric materials’ tensile properties. It is a must for labs that test rubber parts used in automotive seals, tires, hoses, belts, medical devices, and industrial applications.

The standard specifies how to prepare dumbbell-shaped and ring specimens, perform the test using constant speed, and calculate stress-strain values such as tensile strength, elongation at break, and modulus. It also defines acceptable tolerances for machine accuracy and grip configuration.

OEMs and international buyers often require ASTM D412 to confirm that rubber materials meet durability and performance expectations under real-world tension conditions.

5. ISO 6508 – Metallic Materials – Rockwell Hardness Test

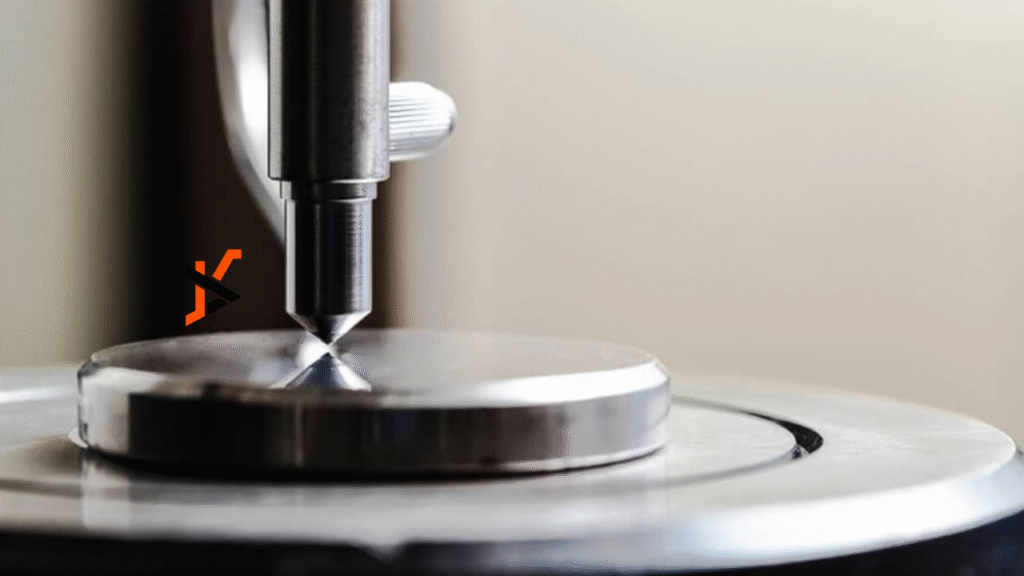

As the last item on our list, ISO 6508 specifies the method for conducting Rockwell hardness tests on metallic materials. It defines multiple Rockwell scales (A, B, C, etc.) and provides procedures for selecting the appropriate scale based on material type and thickness.

The standard includes requirements for indenters, test forces, dwell times, and conversion to other hardness scales. It also outlines calibration and verification methods to verify test outcomes.

Material testing laboratories must comply with ISO 6508 when performing hardness testing for global clients or for regulatory documentation. Using uncertified machines or improper procedures under this standard can result in invalid results and rejected quality certifications.

How to Meet These Industry Standards in 2025

Complying with industry standards is not only about following written procedures—it requires the right infrastructure, equipment, documentation, and partnerships. For material testing laboratories, achieving and maintaining compliance with ISO and ASTM standards involves several essential actions.

First, labs must use certified and properly calibrated testing equipment. Machines such as universal testing machines, hardness testers, and elastomer testing systems must meet mechanical accuracy and repeatability requirements. For example, ISO 6892-1 and ASTM E8 both demand strict control over test speed and force application. Only modern machines with verified calibration certificates can meet these criteria.

Second, laboratories must implement and maintain documented procedures, traceability systems, and training programs that reflect ISO/IEC 17025 requirements. This includes keeping equipment logs, recording environmental conditions during tests, and assuring that all technicians are qualified to perform and interpret test results according to the specified standard.

Another key element is working with accredited partners and equipment suppliers. Partnering with companies that offer pre-certified testing machines, installation, training, and support for audits makes it easier to comply with standards like IATF 16949 or Nadcap. These providers can also assist with periodic calibrations, software updates, and procedural alignment to maintain uninterrupted compliance.

Finally, compliance must be monitored and maintained over time. Many of the listed standards require annual or periodic verification, internal audits, and, in some cases, third-party inspections. Having a system in place for ongoing evaluation helps avoid certification lapses and reduces the risk of non-compliance during customer or regulatory audits.

Building Trust and Accuracy Through Certified Testing

Material testing labs must comply with industry standards in order to maintain their credibility, accuracy, and long-term success in 2025. Standards like ISO/IEC 17025, ASTM E8, ISO 6892-1, ASTM D412, and ISO 6508 define how tests must be performed and how results are accepted globally.

Failure to meet these standards can lead to rejected data, failed audits, lost contracts, or legal penalties. On the other hand, compliance supports product certification, strengthens customer trust, and keeps labs aligned with the evolving demands of the aerospace, automotive, construction, and manufacturing sectors.

To stay compliant, labs must use certified equipment, follow documented procedures, and work with partners that understand testing requirements and can provide ongoing support. Keeping up with these five essential standards is not just about meeting expectations—it is about leading with reliability, precision, and accountability.