Welding regular carbon steel to stainless steel is a common and practical task in many industries. While it’s entirely possible, it requires special knowledge and techniques to create a strong, durable joint. This guide breaks down the challenges, the best methods, and the key practices needed for success.

Why Weld Carbon Steel to Stainless Steel?

The primary reason for joining these two different metals is to get the best of both worlds: performance and cost-effectiveness. Stainless steel is excellent at resisting rust and corrosion, but it’s expensive. Carbon steel is strong and much cheaper. By combining them, engineers can build products that use the corrosion resistance of stainless steel only where it’s needed most, while using carbon steel for structural support, keeping the overall cost down.

A perfect example is a large chemical storage tank. The inside might be lined with stainless steel to prevent the chemicals from eating through the metal, while the outer structure is made of carbon steel for strength and affordability. You can also find this combination in automotive exhaust systems, architectural elements, and industrial piping.

However, joining them isn’t as simple as welding two similar pieces of metal. Their fundamental properties are very different, which can lead to problems like cracking or corrosion if the weld isn’t performed correctly.

The Science Behind the Challenge

The main difficulty lies in the distinct metallurgical differences between carbon steel and stainless steel.

- Thermal Expansion: When heated, stainless steel expands and shrinks about 50% more than carbon steel. As the weld cools, this mismatch creates powerful internal stresses that can warp the materials or even cause the weld to crack.

- Heat Conductivity: Carbon steel draws heat away from the weld area much faster than stainless steel, which tends to hold heat. This imbalance can affect how the molten weld pool behaves and solidifies.

- Weld Chemistry: The most significant challenge is what happens when the metals mix in the molten weld pool. Stainless steel relies on a high chromium content (at least 10.5%) to form a protective layer that stops rust. Carbon steel, as its name suggests, contains more carbon. If too much carbon from the regular steel mixes into the weld, it can bond with the chromium in the stainless steel. This process, called sensitization, “steals” the chromium that is needed for corrosion protection, making the stainless steel near the weld vulnerable to rust. Furthermore, this mixing can create hard, brittle zones (like martensite) in the weld, making it prone to cracking.

The Key to Success: Choosing the Right Filler Metal

Because the base metals are so different, you cannot simply melt them together. The secret to a successful weld is using the correct filler metal. This filler acts as a chemical bridge, creating a weld deposit that is compatible with both the carbon steel and the stainless steel.

Filler metals designed for this task are “over-alloyed” with extra chromium and nickel. This ensures that even after being diluted by mixing with the carbon steel, the final weld still has enough of these elements to remain strong, ductile, and corrosion-resistant.

- Type 309/309L: This is the universal workhorse for joining common stainless steels (like 304 and 316) to carbon steel. It has a high chromium and nickel content specifically designed to prevent cracking and maintain corrosion resistance. The “L” version (309L) has a lower carbon content and is the preferred choice to further reduce the risk of sensitization.

- Type 312: This filler metal is even more crack-resistant and is often used for “difficult-to-weld” or unknown steels.

- Nickel-Based Fillers: For extremely demanding applications, such as those involving very high temperatures, expensive nickel-based fillers offer superior performance and crack resistance.

Best Practices for a Strong Weld

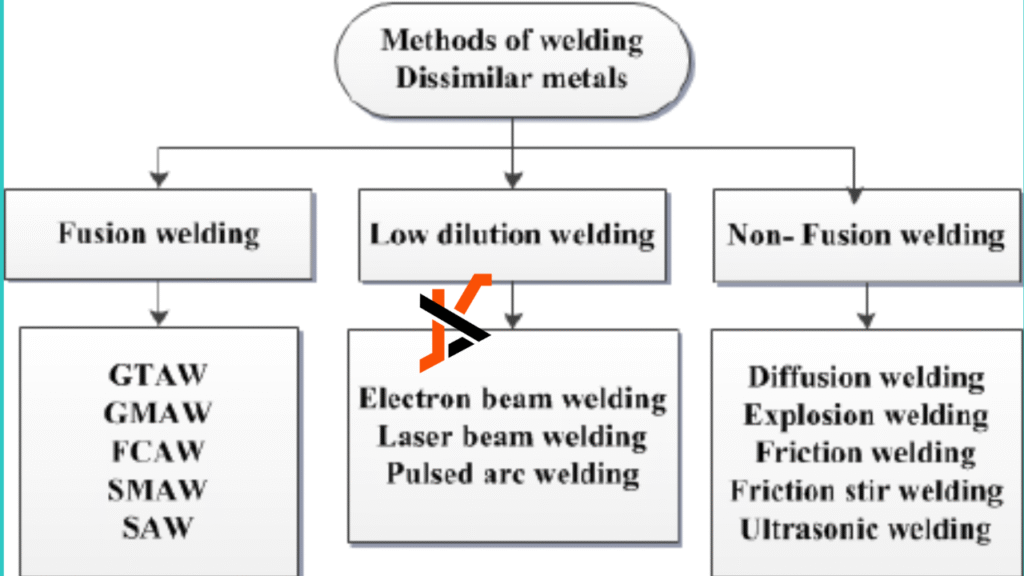

Beyond choosing the right filler, success depends on careful technique and preparation, regardless of whether you are using Stick (SMAW), MIG (GMAW), or TIG (GTAW) welding.

- Meticulous Cleaning: This is the most critical first step. Both the carbon steel and stainless steel surfaces must be completely free of rust, paint, oil, and any other contaminants. Use a dedicated stainless steel wire brush for the stainless part to avoid contaminating it with iron particles.

- Control Your Heat: Use the lowest heat input possible that still achieves good fusion. This minimizes distortion, reduces the risk of sensitization in the stainless steel, and prevents excessive mixing of the base metals. It’s often better to use narrow, straight “stringer beads” rather than wide, weaving motions. Also, allow the workpiece to cool between weld passes.

- Pre-heating (Use with Caution): For thicker sections of carbon steel, pre-heating the carbon steel side to around 50°C to 200°C (120°F to 400°F) can help slow the cooling rate and reduce the risk of cracking. However, avoid excessively heating the stainless steel.

- Avoid Post-Weld Heat Treatment (PWHT): This is a crucial point. The standard heat treatment temperatures used to relieve stress in carbon steel fall directly within the sensitization range for stainless steel. Performing a standard PWHT will severely damage the stainless steel’s ability to resist corrosion. If heat treatment is required by a specific code, you must consult a metallurgical expert.

Advanced Solutions: The Laser Welding Advantage

Modern techniques using a laser welding machine offer significant advantages for joining dissimilar metals. A laser provides a highly focused beam of energy, which results in:

- Extremely Low Heat Input: This drastically reduces the heat-affected zone, minimizing distortion and the risk of sensitization.

- High Welding Speed: Laser welding is very fast, which improves productivity.

- Precision and Control: The process is highly controllable, leading to clean, high-quality welds.

Manufacturers like Riselaser have developed advanced laser welding machines that provide the precision and control needed for these challenging applications.

Another advanced technique is “buttering,” where a layer of compatible filler metal (like Type 309) is first welded onto the edge of the carbon steel. After this “buttered” layer cools, the part can be treated more like a stainless steel component, simplifying the final weld to the actual stainless steel piece.

Conclusion

Welding regular steel to stainless steel is a well-established and valuable industrial process. Success hinges on understanding and managing the metallurgical differences between the two metals. By selecting the correct filler metal (usually Type 309L), meticulously cleaning the materials, controlling heat input, and avoiding improper heat treatments, fabricators can reliably create strong, cost-effective, and corrosion-resistant hybrid components that leverage the best properties of each material.