Key Takeaways:

• Undetected wastewater pollutants can lead to environmental damage, legal penalties, and operational shutdowns.

• Standard periodic testing often misses transient discharges caused by fluctuating facility conditions.

• Routine maintenance and outdated infrastructure can introduce contaminants that go unmonitored.

• Upcoming EPA regulations, like the 2026 MSGP, signal increased scrutiny of industrial wastewater and stormwater systems.

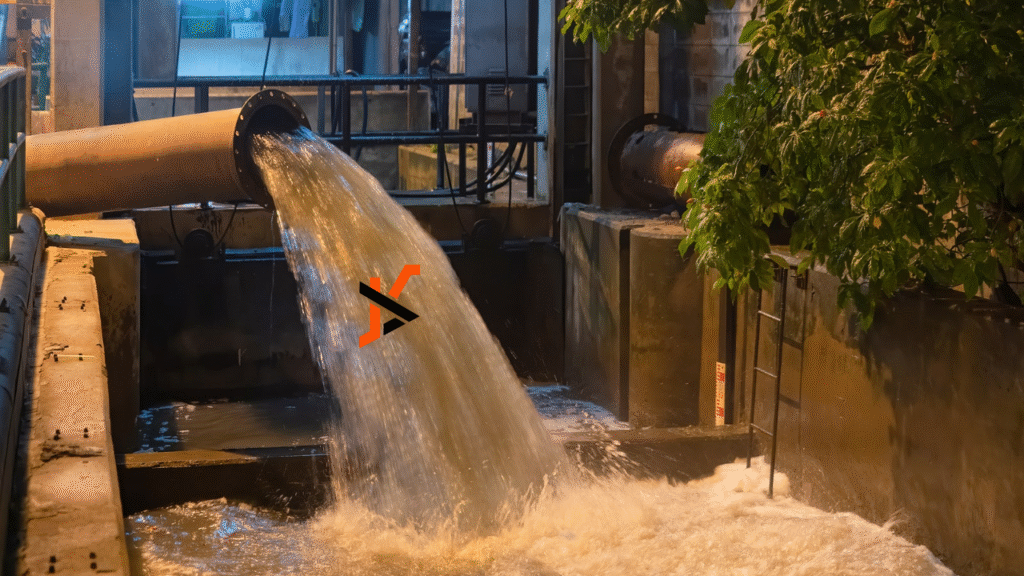

Not all wastewater issues are immediately apparent. Behind the hum of daily operations, facilities may unknowingly release pollutants that evade detection — until the consequences surface. These hidden threats don’t just put your environmental compliance at risk; they can lead to fines, reputational damage, and even operational shutdowns.

In an era where sustainability and accountability are under sharper scrutiny than ever, what escapes a facility’s monitoring system could become its next crisis. Overlooked contaminants in wastewater can disrupt ecosystems, harm public health, and create liabilities that grow more costly with time. So, the question stands: What might you be missing?

Why Wastewater Testing Might Not Tell the Full Story

Periodic testing and sampling are standard practices for monitoring wastewater. However, these methods have limitations. Conditions within a facility can change between tests due to factors like peak operational hours or seasonal shifts. Such fluctuations may lead to transient discharges that go undetected by scheduled testing, potentially resulting in noncompliance and environmental harm.

What Are the Most Commonly Missed Pollutants?

Certain pollutants often escape detection, including trace metals, hydrocarbons, surfactants, and unmonitored organic compounds. Even in small quantities, these substances can accumulate over time, leading to significant environmental issues. Facilities might not monitor these pollutants if they’re not explicitly listed in discharge permits, yet their presence can still pose serious risks.

How Do Maintenance Practices Contribute to Wastewater Risk?

Routine activities such as washing oily parts or flushing solvents can inadvertently introduce contaminants into wastewater systems. There’s a common misconception that certain cleaning agents are harmless due to their biodegradability. However, some biodegradable substances can still cause environmental damage if not properly managed. Internal operations, if not carefully monitored, can silently breach environmental compliance.

What Happens When Stormwater Meets Industrial Waste?

Stormwater runoff and industrial waste often share more than just a facility’s real estate. They can co-mingle through drains, trenches, or overflow systems, creating complex compliance challenges. Cross-contamination is especially risky in facilities with open yard areas or older drainage infrastructure, where even a brief rainfall can mobilize hazardous residues.

Regulators are catching up to these realities. In April 2025, the U.S. Environmental Protection Agency proposed its new 2026 Multi-Sector General Permit (MSGP), which will govern stormwater discharges from industrial sites across all 10 EPA regions. With the current MSGP expiring in early 2026, this new draft signals tighter scrutiny for commercial contractors engaged in vehicle maintenance, equipment storage, or manufacturing, especially near waterways.

Facilities that treat stormwater separately from industrial wastewater may still face risk if those systems aren’t regularly audited or are excluded from current discharge monitoring protocols. Could your stormwater system be an unmonitored discharge point?

Are Your Current Interception Systems Working as Promised?

Interception systems like oil-water separators are designed to prevent pollutants from entering wastewater. However, aging equipment, design flaws, or inadequate maintenance can compromise their effectiveness. Regular performance assessments are crucial to ensure these systems function correctly. An installed solution doesn’t guarantee a resolved problem; ongoing evaluation is essential.

Why Looking Deeper Into Wastewater Pays Off

Ignoring invisible wastewater risks can lead to significant environmental and legal consequences. Addressing these issues is not just about compliance. It’s about protecting communities and ecosystems. A deeper examination of your facility’s wastewater practices may reveal hidden threats that, once identified, can be effectively managed. What would you uncover if you looked deeper?

Martin Alan is the CEO and owner of Vodaland, overseeing operations across the United States, Puerto Rico, and the Virgin Islands. With over a decade of experience in the building technologies industry, he has led efforts in business development, product innovation, and customer-driven solutions. Under his leadership, Vodaland continues to advance smart building solutions, offering high-performance products such as industrial oil water separator and tailored services to clients nationwide.