In today’s rapid manufacturing world, precision is everything. Handheld laser welders are revolutionizing the way metalwork is done, offering unmatched accuracy and versatility. With these powerful tools, you can achieve clean, strong welds on various materials without the need for bulky equipment.

The Rise of Handheld Laser Welder Technology

Handheld laser welders bring a new level of precision and accessibility to metalwork. Their technology continues to gain traction across various industries, primarily due to its efficiency and versatility.

Handheld Laser Welder and Its Core Principle

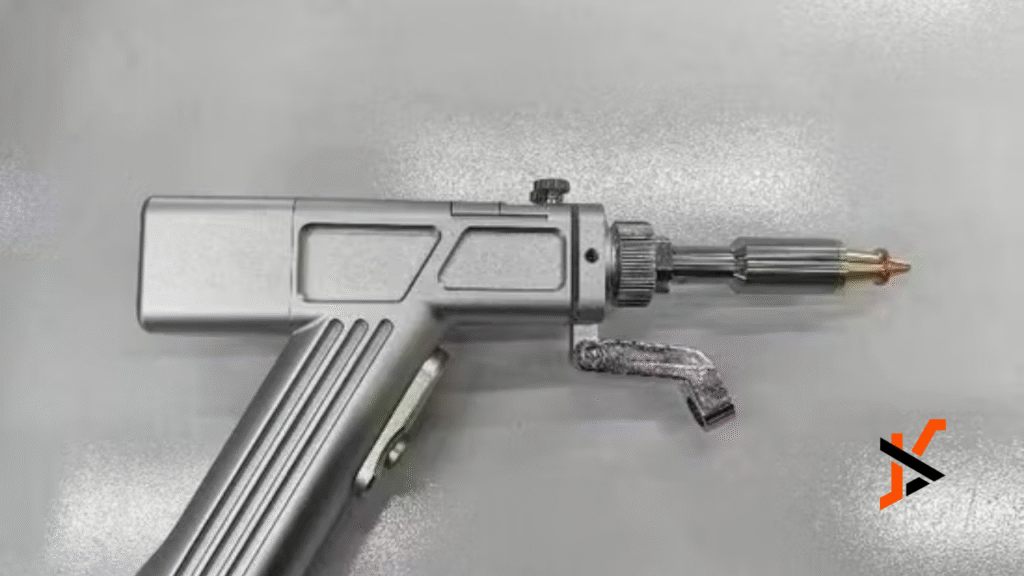

A hand held laser welder operates on the principle of focused laser energy. They direct a high-intensity beam onto metal surfaces, causing a rapid melting effect. This process yields strong, clean welds that require minimal cleanup. Users can customize power settings to adjust the depth and width of the weld, allowing them to fit specific materials or applications.

How does Denaliweld leverage this Innovation?

Denaliweld applies advanced optics in its handheld laser welders, enhancing focus and control. Their models are compact yet powerful, allowing for easy maneuverability. With integrated cooling systems, these welders maintain consistent performance during extended use. This ensures you achieve high-quality results across different metal types, from aluminum to stainless steel.

Technology Fundamentals

Handheld laser welders use a non-contact method to fuse metal surfaces. These units direct a high-energy laser onto a small area, which quickly melts and solidifies the metal, resulting in strong welds. They reduce heat-affected zones to around 0.5 mm, lowering distortion and minimizing the need for finishing work.

Laser Source & Beam Parameters

The laser source emits a high-power-density beam that forms deep, narrow welds. A specific configuration enables the joining of thin plates, such as stainless steel and galvanized materials, with a tolerance of just 0.1 mm. This capability preserves material quality by limiting the spread of heat.

Wobble / Oscillation Capability

Many handheld laser welders come with oscillation features. These enable lateral movement during welding, which broadens the weld seams. Such control improves joint strength and weld bead shape, minimizing deformation and enhancing overall quality.

Ergonomics & Mobility

Lightweight design is a standout feature of these welders. The welding head typically weighs about 2.2 lbs, allowing for easy handling and reduced operator fatigue. The separate, heavier power unit (approximately 27 kg) contributes to portability, making these devices suitable for use in confined spaces and complex shapes. Features like drag-tip designs help streamline workflows.

Key Performance Metrics & Specifications

Handheld laser welders improve metal precision through advanced features and specifications. Their capabilities are important to understand for effective application.

Energy Density & Penetration

Handheld laser welders utilize concentrated beams that can penetrate deeply into metals, allowing for precise control of weld depth and width. This energy density helps create strong joints with reduced microstructural damage.

Welding Speed & Productivity

Compared to traditional welding methods, handheld laser welders operate 5 to 10 times faster. The high-energy beam allows rapid melting and fusion, thereby increasing production cycles. This speed can lead to decreased labor costs and enhanced output.

Material & Thickness Compatibility

Handheld laser welders offer versatility in terms of materials and thicknesses. They can work with various metals, including stainless steel, carbon steel, aluminum, copper, brass, titanium, and nickel alloys. Dissimilar metal welding is possible, which broadens your options for industrial applications.

Thickness Capabilities by Laser Power

The thickness that can be welded depends on the laser power and other factors, such as beam quality and cooling efficiency. Below is a table detailing thickness capabilities:

| Laser Power | Typical Max Thickness (Steel) | Benefits |

|---|---|---|

| 300W | ~0.3 mm | Suitable for very thin material |

| 600W | ~1 – 1.5 mm | Best for materials thinner than 1 mm |

| 1000W | 2 – 3 mm | Enables high-speed welding |

| 1500W | 4 – 5 mm | Moderate thickness, moderate speed |

| 2000W | 6 – 8 mm | Effective for thicker materials |

| 2500W+ | Up to 8 – 10 mm | Newer models achieve 10 mm in one pass |

Material-Specific Thickness Examples

- Stainless steel: Welds up to 8 mm, depending on laser power.

- Carbon steel: Capable of welding from 1 mm to 10 mm.

- Aluminum: Generally, it welds up to 6 mm, with best results usually achieved at 1-2 mm, considering its thermal properties.

Welding Without Wire Feed

Laser welding under 1 mm thickness usually works best without wire feed. This approach helps prevent deformation and maintains speed. For welds exceeding 0.3 mm, adding wire may enhance quality but can slow down the process.

What approach do you find effective for different materials?

Data & Automation Interfaces

Handheld laser welders integrate data and automation features, enhancing usability and precision. Operators can adjust settings based on real-time data, leading to more consistent welds.

Key Automation Features

- Adjustable Laser Parameters: You can adjust the intensity and pulse duration for various applications. This allows for tailored welding depending on metal type and thickness.

- Integrated Cooling Systems: These systems help maintain stability during operation, ensuring optimal performance across a wide range of materials.

- User Interface: Most models feature screens that display relevant data, simplifying monitoring and adjusting settings on the fly.

Automation technologies streamline workflows, making handheld laser welders a practical choice for various metalworking tasks. As you consider different models, reflect on how these features can suit your specific needs.

Practical Applications

Handheld laser welders find diverse applications in various sectors. They deliver precision and speed, making them invaluable tools for a wide range of metalworking tasks.

Sheet-Metal Fabrication

Handheld laser welders are well-suited for use in sheet-metal fabrication. The ability to create clean, strong welds on thin materials reduces the risk of damage. You can tackle challenging metals like aluminum and copper, enabling new fabrication possibilities for products like stainless steel kitchenware and aluminum window frames.

Automotive & E-Mobility

In the automotive sector, these devices facilitate the welding of structural components, such as doors and chassis. Their adaptability to different metal types, particularly in e-mobility vehicles, stands out. Precision in welding aids in lightweighting and enhances the durability of electric vehicle components.

Aerospace & Defense

Aerospace applications benefit from the ability of handheld laser welders to create fine, high-strength welds. The minimal heat distortion suits heat-sensitive materials, such as titanium and specialized alloys. Meeting stringent safety and quality standards is crucial, and this technology aligns well with those requirements.

Maintenance & Field Repair

For maintenance tasks and field repairs, handheld laser welders shine in portability and ease of use. They perform on-site maintenance for machinery, vehicles, and infrastructure efficiently. This capability reduces downtime and enhances serviceability, proving it valuable in various operational scenarios.

Conclusion

Handheld laser welders significantly improve metal precision in various applications. They deliver high-quality welds with minimal distortion.

Handheld laser welders are well-suited for welding various materials, including aluminum, carbon steel, and stainless steel. Their usability across multiple sectors, such as automotive and aerospace, showcases their versatility. Would a handheld laser welder be suitable for your specific projects?