If you’ve ever imagined huge mining machines digging into asteroids or scooping up Moon dust, you’re already picturing the future that’s slowly taking shape. But here’s the reality – none of that will happen without automation. Robots and smart systems are stepping in to handle the jobs that are too dangerous, too slow, or simply impossible for humans in space.

And as we’ll see, automation isn’t some far-off fantasy. It’s the missing link that could turn space mining from a concept into an industry.

Why Automation Is Essential in Space Mining

When you think about space mining, it’s easy to focus on the exciting part – finding valuable materials and bringing them back. But before we get there, we have to solve a huge problem: space is not built for humans. Imagine trying to operate heavy machinery on an asteroid when there’s no air, very little gravity, and a constant risk of radiation exposure. Every move has to be planned and executed with perfect timing.

That’s where automation shines. Let’s see some examples:

- One big challenge is communication delay. Depending on where the spacecraft is, sending a command from Earth could take several minutes to reach it, and then you’d have to wait for the reply. This makes remote control clumsy and inefficient. Automated systems don’t wait – they sense, decide, and act instantly.

- Then there’s the danger factor. Robots don’t need oxygen, temperature control, or a ride home. They can withstand the cold, the dust, and the unpredictable terrain without putting a human life at risk. And because they don’t need the same safety systems, they’re lighter and cheaper to launch.

In short, without automation, space mining would be like trying to dig a tunnel using only your hands – it’s technically possible, but not practical.

What’s Already Happening in Space Mining Automation

Automation in space mining isn’t just a theory. Several companies and space agencies are already testing the machines and processes that could make it work. For example, small spacecraft are being developed to travel to asteroids, take samples, and process materials on-site. The goal is to prove that these robots can not only survive in harsh environments but also work efficiently without constant human guidance.

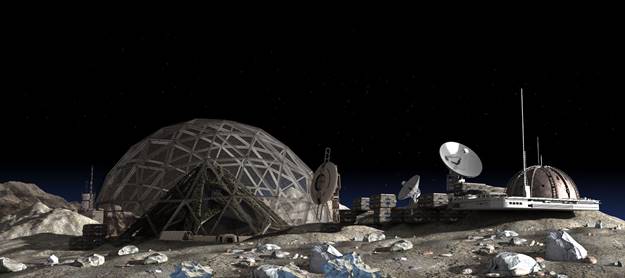

Some startups are experimenting with techniques like using concentrated sunlight to break apart rock and release valuable materials. Others are creating mining “fleets” that can extract resources and deliver them where they’re needed, whether that’s an orbiting refinery or a lunar base. These aren’t prototypes gathering dust in a lab – many have already been launched into space for real-world testing.

Even large space agencies are getting involved. NASA and others are exploring ways to combine mining robots with construction robots. The idea is to build infrastructure – like fuel depots or living quarters – directly from the materials mined on-site. If successful, this approach would cut costs and make space exploration far more sustainable. It’s a sign that automation isn’t just part of the plan; it’s at the center of it.

Lessons from Earth’s Mining Industry

While space mining is new, the idea of using automation to dig and process materials isn’t. On Earth, the mining industry has been using autonomous trucks, drilling rigs, and processing plants for years. These machines can work around the clock, handle dangerous conditions, and maintain consistent productivity without the limitations of human crews.

This experience on Earth matters because it shows that automation in mining isn’t just possible – it’s profitable. The same principles can be adapted for space. Sure, the environment is harsher and the stakes are higher, but the core technology – sensors, autonomous navigation, precision machinery – already exists. It’s a matter of modifying it for zero gravity, vacuum conditions, and extreme temperatures.

Seeing how well automation has worked here at home should give us confidence. If robots can manage open-pit mines in remote deserts or deep underground operations, they can also be trained – so to speak – to mine a distant asteroid.

The Technical Hurdles We Still Need to Overcome

Of course, automation doesn’t make space mining easy – it just makes it possible. There are still big challenges that engineers are working to solve. One is dust. Lunar and asteroid dust is incredibly fine and sharp. It can clog joints, scratch surfaces, and interfere with sensors. Designing robots that can keep working without being damaged by dust is a major focus.

Processing materials in space is another challenge. On Earth, mining involves crushing, washing, and refining materials, often with heavy equipment. In space, you can’t just use water or let gravity help separate different particles. New methods are being developed to process rock in a vacuum and without relying on Earth-like conditions.

And then there’s the matter of autonomy itself. These machines have to operate without a lot of human input, which means they need reliable software, backup systems, and the ability to recover from small failures on their own. Building that level of resilience into a spacecraft is no small feat, but progress is happening.

Why This Matters for the Future

So why should we care? The short answer is that automation could unlock resources we can’t easily get on Earth. Some asteroids contain platinum, gold, and rare earth elements in much higher concentrations than anything in terrestrial mines. Others have water ice, which can be broken down into hydrogen and oxygen to make rocket fuel. That means mining in space could directly support space travel itself.

It’s not just about money and fuel, either. Automation makes it possible to build and maintain infrastructure in space – without needing to launch every piece from Earth. Imagine satellites being refueled in orbit, lunar bases built from lunar rock, or even giant solar power stations in space. All of this depends on extracting and using local resources, and automation is the only realistic way to make that happen.

If the technology continues to advance, we could eventually shift some heavy industry off Earth entirely. That would reduce environmental damage here at home and open up new possibilities for space exploration. In many ways, automation is the foundation for the next stage of our journey beyond Earth.

Closing Thoughts

Automation is moving space mining from fiction to fact. By removing human limits, cutting costs, and working without delays, it makes resource extraction beyond Earth feasible.

Challenges like dust, zero-gravity processing, and fully autonomous operation remain, but they are solvable. With continued progress, large-scale robotic mining could begin within a decade – laying the groundwork for a new space economy where machines handle the labor and humans focus on exploration and innovation.