The debate between electric motors and internal combustion engines (ICEs) has been a subject of intense discussion for decades. As the world continues to evolve technologically and environmentally, this debate has grown even more critical, especially with the push toward reducing carbon emissions and achieving sustainability goals. Toshiba electric motors are at the forefront of this transformation, offering innovative solutions that could potentially replace traditional internal combustion engines in a variety of applications.

Both electric motors and internal combustion engines have their distinct advantages, but the real question is: Which one is better for the future of transportation, industry, and energy? To answer this, we need to understand the differences between the two technologies, their applications, and the environmental and economic implications that each brings. In this article, we will explore the strengths and weaknesses of electric motors and internal combustion engines, analyzing how they compare in performance, efficiency, environmental impact, and cost-effectiveness.

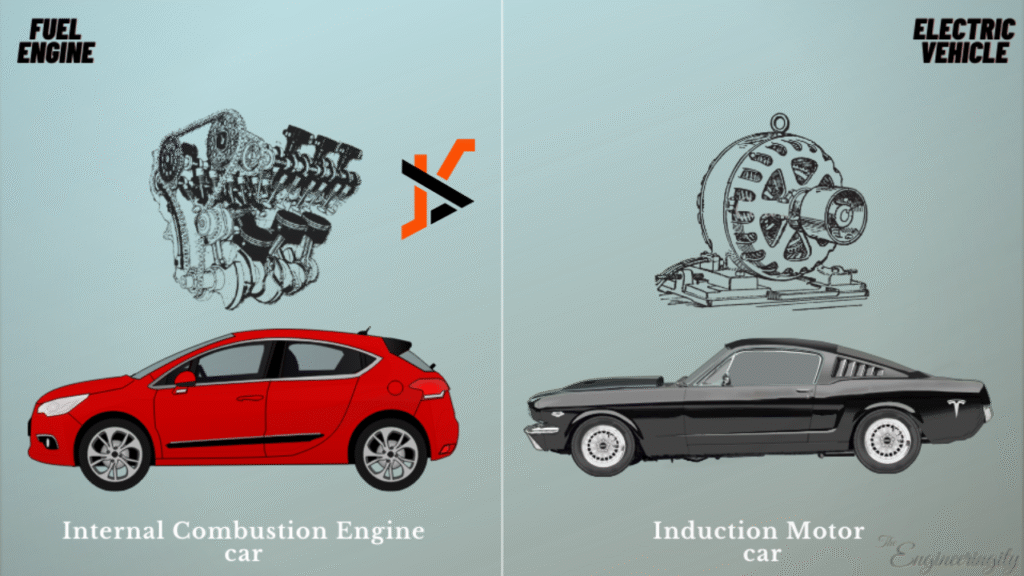

Understanding the Basics: Electric Motors vs. Internal Combustion Engines

Before comparing the two, it’s essential to grasp how electric motors and internal combustion engines operate.

Electric Motors

Electric motors operate by transforming electrical energy into mechanical motion using the interaction of magnetic fields. When electricity flows through the motor’s windings, it generates a magnetic field that interacts with a permanent magnet or electromagnet, causing the motor’s rotor to turn. The simplicity of this mechanism results in high efficiency and smooth operation.

Internal Combustion Engines (ICEs)

Internal combustion engines operate by burning fuel (such as gasoline, diesel, or natural gas) in a combustion chamber. This process releases energy in the form of heat, which expands gases that push pistons, creating mechanical energy to power the engine. ICEs have been the backbone of transportation and industrial machinery for over a century, with vast networks built around them, from fuel infrastructure to maintenance systems.

Efficiency: Which is More Energy-Efficient?

One of the key points of comparison between electric motors and internal combustion engines is efficiency. Efficiency refers to how effectively a system converts input energy (fuel or electricity) into usable work (mechanical power).

Electric Motors’ Efficiency

Electric motors are known for their high efficiency. In fact, they can achieve efficiencies upwards of 90%, with some well-designed models even surpassing 95%. This is primarily because electric motors waste very little energy in the form of heat compared to ICEs. In addition, electric motors can operate at variable speeds with minimal energy loss, making them ideal for applications that require precision control and adaptability.

Internal Combustion Engines’ Efficiency

Internal combustion engines are far less efficient, typically converting only around 20-30% of the energy from the fuel into useful mechanical power. The rest of the energy is lost as heat, which is why ICEs require extensive cooling systems. Additionally, ICEs are not as efficient at partial load, meaning they waste more fuel when not running at full capacity. This inherent inefficiency results in a significant energy loss and lower overall performance compared to electric motors.

Environmental Impact: Which is More Environmentally Friendly?

As the world grapples with climate change and seeks ways to reduce its carbon footprint, the environmental impact of electric motors and internal combustion engines becomes increasingly important.

Electric Motors and Sustainability

Electric motors are widely considered the more environmentally friendly option. When paired with renewable energy sources such as wind, solar, or hydroelectric power, electric motors produce minimal to no carbon emissions. This makes them a critical part of the transition to a more sustainable future. Even when charged from the electrical grid, which may still rely on fossil fuels, electric motors contribute to a cleaner overall energy system due to their high efficiency.

Moreover, electric vehicles (EVs), which rely on electric motors, are often touted as a solution to reducing air pollution, especially in urban areas. EVs have no tailpipe emissions, contributing to cleaner air and lower levels of harmful pollutants like nitrogen oxides and particulate matter.

Internal Combustion Engines and Pollution

Internal combustion engines, on the other hand, are a significant source of air pollution. The combustion of fossil fuels in ICEs releases carbon dioxide (CO2), nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter into the atmosphere. These emissions contribute to global warming, smog formation, and various health problems such as respiratory issues.

While efforts have been made to improve the efficiency and reduce the emissions of internal combustion engines (through cleaner fuel technologies, catalytic converters, and more), they still remain a major contributor to environmental degradation. The extraction and refinement of oil, in addition to the burning of fuel, all contribute to the overall environmental impact of ICEs.

Maintenance and Longevity: Which is Easier to Maintain?

The complexity of a system often determines how much maintenance it requires. An engine with more moving parts typically demands more regular care to ensure smooth performance and longevity.

Electric Motors’ Maintenance Requirements

Electric motors feature a more straightforward design and contain fewer moving components than internal combustion engines. This simplicity translates into lower maintenance costs and less frequent repairs. In many cases, electric motors have no need for oil changes, exhaust systems, or fuel filters. The primary maintenance tasks for electric motors are typically related to bearings and electrical components, which are less prone to wear and tear compared to the mechanical parts of an ICE.

Furthermore, electric motors operate much quieter than internal combustion engines, and they do not experience the vibrations that are characteristic of ICEs. This makes them more comfortable to operate and less prone to mechanical fatigue.

Internal Combustion Engines’ Maintenance Challenges

Internal combustion engines are much more complex, with a wide array of moving parts such as pistons, crankshafts, camshafts, and valves. These parts need consistent lubrication, cooling, and upkeep to avoid wear and potential failures. Additionally, the fuel system in ICEs often requires cleaning or replacement, and the exhaust system must be monitored for leaks or blockages.

The complexity of an ICE means that it is more prone to mechanical issues over time, leading to higher maintenance costs. Regular oil changes, spark plug replacements, and fuel system servicing are just a few examples of the maintenance required to keep an internal combustion engine running smoothly.

Cost-Effectiveness: Which One Offers Better Value?

While the performance and environmental considerations are important, the economic aspect of choosing between electric motors and internal combustion engines cannot be overlooked. The upfront cost, operating expenses, and long-term value must all be considered.

Electric Motors and Cost

Electric motors typically have a higher initial purchase cost, particularly when integrated into electric vehicles or other systems that require specialized batteries or infrastructure. However, electric motors generally have lower operating costs due to their energy efficiency and minimal maintenance needs. With fewer moving parts and less frequent breakdowns, the long-term cost of ownership is often lower than that of an internal combustion engine.

Moreover, as the global adoption of electric vehicles grows, the price of electric motors and batteries continues to decrease. Government incentives for EVs also help make electric motors a more attractive option financially.

Internal Combustion Engines and Cost

Internal combustion engines tend to be less expensive upfront, especially when considering their widespread use in cars, trucks, and industrial machines. However, the ongoing costs of fuel, maintenance, and repairs can add up significantly over time. Additionally, as countries implement stricter emission regulations, the cost of compliance for ICE manufacturers may increase, further raising the overall cost of ownership.

Conclusion: Which is Better?

The question of which technology—electric motors or internal combustion engines—is better depends on the context. Electric motors are superior in terms of efficiency, environmental impact, maintenance, and long-term value. Their simplicity, low operational costs, and zero-emission capabilities make them the preferred option for many industries, especially as the world transitions to cleaner energy.

Internal combustion engines, while still widely used and less expensive upfront, have inherent inefficiencies and environmental drawbacks that make them less sustainable in the long run. The shift toward electric motors, particularly in transportation and industrial applications, seems inevitable, driven by the need for cleaner energy and reduced reliance on fossil fuels.