Unplanned equipment failures can bring operations to a halt, leaving businesses facing high repair bills, wasted resources, and missed opportunities. In industries where every minute counts, keeping systems running smoothly is not only about convenience but about protecting revenue and maintaining a competitive edge.

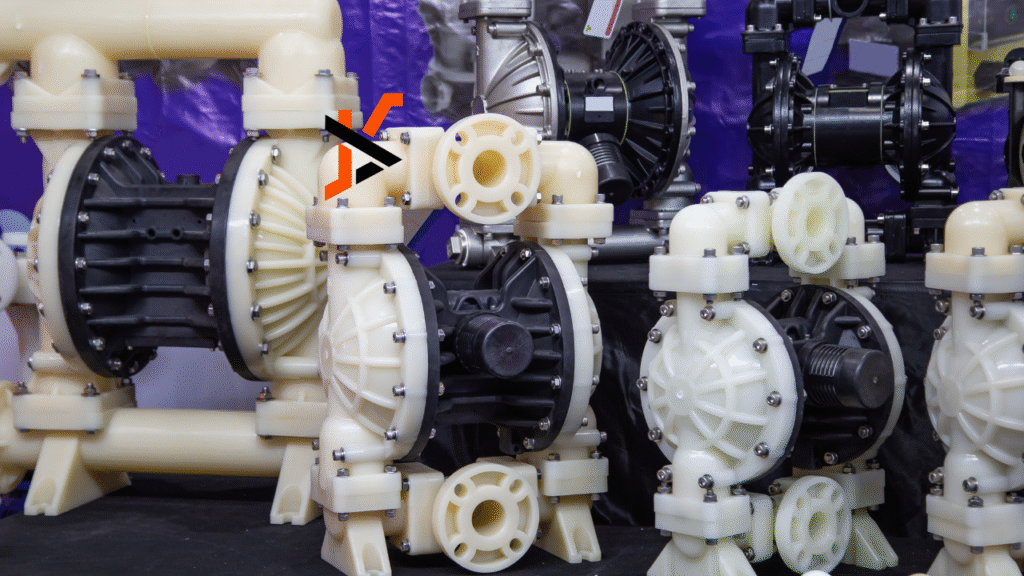

Gas diaphragm pumps stand out as a dependable choice because of their rugged construction, ability to handle demanding materials, and simple maintenance requirements. These features help reduce the risk of costly interruptions and give businesses more control over their operations. Beyond reliability, they also contribute to long-term savings and improved productivity by ensuring equipment performs at its best.

Read on to see how gas diaphragm pumps reduce downtime and boost revenue in ways that directly impact your bottom line.

Lowering Maintenance and Repair Costs

Maintenance is often one of the highest hidden costs in pumping systems, but diaphragm pumps are designed to ease that burden. Their construction allows them to run longer with fewer issues, giving businesses a practical way to keep operating budgets in check.

Partnering with the right supplier also makes a significant difference. Working with knf.com/en/global or another trusted provider of gas diaphragm pumps ensures access to innovative, reliable solutions that precisely and safely transfer gases and liquids for medical, industrial, and research applications. This level of engineering extends the usable life of equipment and reduces the likelihood of costly breakdowns.

The following are ways gas diaphragm pumps cut down on maintenance and repair costs:

- Extended lifespan: Pumps built with features such as a double diaphragm design, durable sealing rings, and strong diaphragm materials like fiber-core synthetic rubber diaphragm are less prone to wear. This durability means they stay in service longer before replacements are required.

- Easy part replacement: Components like the pump rod, fluid port, and automatic valves are straightforward to replace when needed. Quick swaps reduce labor hours, eliminate the need for specialized service teams, and help restore operations faster.

- Reduced service frequency: With strong chemical compatibility and chemical resistance, these pumps handle challenging fluids without frequent failures. A safety diaphragm system or safety double diaphragm adds extra protection against leaks, further lowering the need for ongoing service calls.

Lower maintenance needs translate into more than just cost savings. They also free up resources for growth initiatives, whether that means scaling production, investing in new equipment, or supporting research and development.

Minimizing Equipment Downtime

Unplanned breakdowns can cause serious interruptions, and every hour of lost production cuts into profitability. Gas diaphragm pumps are designed to keep equipment running longer with fewer unexpected stoppages. Their straightforward design focuses on reliability, which helps reduce the risk of downtime that slows operations.

Here’s how diaphragm pumps reduce downtime:

- Fewer moving parts: With less internal complexity compared to alternatives like a centrifugal pump or a piston pump, there are fewer areas prone to mechanical failure. This simplified build translates into more consistent operation and fewer unplanned shutdowns.

- Durable materials: Components such as the fiber-core synthetic rubber diaphragm and specialized sealing rings are built to withstand pressure, temperature fluctuations, and continuous use. These features reduce material fatigue and help extend operating cycles.

- Quick maintenance: When service is required, straightforward access to parts like the pump rod and automatic valves makes repairs faster. Maintenance teams can restore pump performance without extensive downtime or delays waiting for complex servicing.

These strengths ensure production processes run more reliably, reducing costly interruptions and allowing businesses to stay focused on output rather than repairs.

Improving Operational Efficiency

Operational efficiency depends on equipment that can consistently perform under demanding conditions. Gas diaphragm pumps are designed to maintain stable output, which reduces the fluctuations that often interrupt production. This reliability ensures that manufacturing lines and processes run with fewer interruptions and greater precision.

In addition, their ability to handle materials with varying levels of viscosity and corrosiveness makes them suitable across a wide range of applications. Unlike equipment that struggles with challenging substances, diaphragm pumps continue operating without clogging or performance drops. As a result, businesses can keep production schedules on track even when processing difficult fluids or gases.

Furthermore, the flexibility of these pumps adds another layer of efficiency in specialized environments. Since they can operate independently of electricity, they remain effective in remote locations or hazardous sites where power supply is limited. This adaptability allows businesses to sustain output in areas where conventional systems would be less reliable.

Driving Revenue Growth

Revenue growth depends on reliable equipment that supports uninterrupted operations. Gas diaphragm pumps allow businesses to maintain production targets by avoiding the delays and losses that come with unexpected failures. This consistent output creates a stronger foundation for meeting customer demand and generating more sales.

As operations remain steady, efficiency improvements make it possible to handle larger workloads without requiring significant new investments. Companies can scale production alongside market opportunities while keeping costs under control. With greater capacity, they are better positioned to capture increased revenue.

On top of these gains, the savings realized from fewer repairs and less downtime strengthen overall profit margins. Those freed-up resources can then be directed toward business expansion, innovation, or pricing strategies that attract more customers. Over time, this combination of steady output and smarter reinvestment drives lasting financial growth.

Final Thoughts

Gas diaphragm pumps combine durability, efficiency, and low maintenance to reduce costly downtime while driving revenue growth. Their ability to keep production steady and costs under control makes them a valuable asset for businesses that cannot afford interruptions. Investing in these pumps strengthens operations and supports long-term profitability.