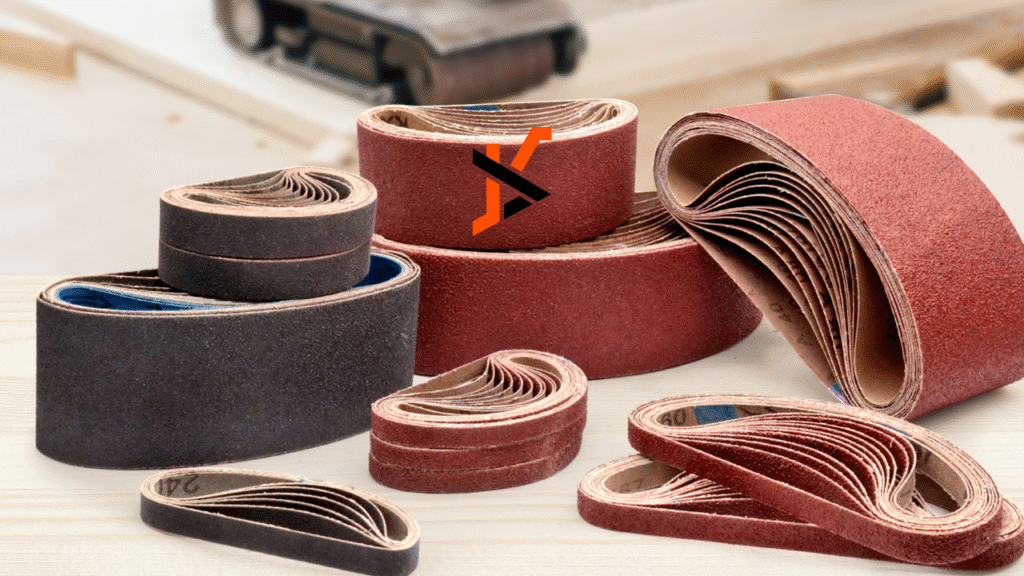

Belt sandpaper is a crucial tool in workshops and industrial settings, designed to provide rapid and efficient material removal. Unlike handheld sandpapers, belt sandpapers are mounted on machines, allowing continuous sanding over larger surfaces. Their design ensures uniform pressure and consistent results, making them ideal for shaping, smoothing, and finishing wood, metal, or other materials.

The quality of belt sandpaper directly affects the efficiency of sanding operations. High-quality belts maintain sharp abrasive grains and strong adhesive backing, providing durability and long-lasting performance. Using premium belt sandpaper reduces downtime due to frequent replacements and ensures a smoother, more precise finish on the workpiece.

Belt sandpaper comes in various grit sizes to suit different applications. Coarse grits are suitable for heavy material removal, medium grits for smoothing rough surfaces, and fine grits for polishing delicate finishes. Choosing the correct grit ensures optimal results and improves the overall efficiency of the sanding process.

Applications of Belt Sandpaper

Belt sandpaper is widely used in woodworking, metal fabrication, automotive workshops, and construction. In woodworking, it helps shape, smooth, and finish surfaces, from rough-cut lumber to delicate furniture pieces. Its ability to cover large surfaces quickly makes it invaluable for time-sensitive projects.

In metalworking, belt sandpaper is used for grinding, deburring, and finishing metal components. It ensures uniform surface preparation before painting or coating, enhancing the durability and appearance of the finished product. Professionals rely on belt sandpaper to achieve consistent, high-quality results in industrial and craft settings.

Belt sandpaper is also common in automotive bodywork. Technicians use it to sand panels, remove paint or rust, and prepare surfaces for refinishing. Its efficiency allows workers to complete large-scale sanding tasks quickly while maintaining a smooth and uniform finish. Choosing the right belt sandpaper for each material and application is critical for optimal results.

Advantages of High-Quality Belt Sandpaper

Investing in high-quality belt sandpaper provides numerous benefits. Durable belts maintain their abrasive properties longer, reducing the need for frequent replacements and minimizing downtime. Consistent abrasive performance ensures even surface finishes, which improves productivity and reduces rework.

High-quality belt sandpaper also offers superior adaptability. It can conform slightly to uneven surfaces while maintaining consistent contact, allowing precise sanding without damaging the workpiece. This makes it suitable for a wide range of materials and applications, from rough shaping to final polishing.

Safety and efficiency are additional advantages of premium belt sandpaper. Inferior belts may tear, wear unevenly, or clog with debris, potentially causing accidents or imperfect finishes. Reliable products ensure a smooth, continuous sanding process, enabling faster, safer, and more precise work in workshops and industrial environments.

Choosing the Right Belt Sandpaper

Selecting the appropriate belt sandpaper requires careful consideration of grit size, backing material, and intended application. Coarse grits are ideal for rapid stock removal, medium grits for smoothing, and fine grits for finishing surfaces. Using the correct grit improves efficiency and guarantees a high-quality finish.

The backing material of the belt also affects performance. Cloth-backed belts offer flexibility and durability for demanding sanding tasks, while paper-backed belts are suitable for lighter applications. Choosing the proper backing ensures optimal sanding results and extends the life of the belt.

The abrasive material plays a key role in performance. Aluminum oxide, silicon carbide, and ceramic grains each offer unique advantages depending on the material being sanded. Selecting high-quality belt sandpaper tailored to the project requirements ensures consistent results, long-lasting performance, and professional-grade finishes.