When building critical infrastructure, the small parts sometimes matter the most. Pneumatically controlled valves might not steal the spotlight, but they are the hidden heroes that keep everything running smoothly. Since safety and efficiency are the main goals of any successful project, many engineers are now weighing high-tech features—like remote control and live feedback data—before they pick a valve. For companies that work on complex control systems, those unassuming little valves become huge players in the overall design. Because they move air instead of fluid, these pieces of gear need a special type of technology, which we usually call air actuator valves. Anyone who has managed a big-site deadline knows that limits—budget, space, time—quickly turn into real problems.

Know the Standards Inside and Out

Almost every industrial part or piece of equipment comes with a basic guide that explains its intended use and how it fits into the bigger picture. When you’re trying to pick the right air actuator valve, the first thing you really need to do is hammer out exactly what the discharge valve has to do for the job at hand. It’s only after that, and only after you have a firm grip on all the industry standards, that you can ask whether the valve can do even more than what’s required. In plants where teams are using hydraulic methods to treat water during oil recovery, the whole operation depends on tight planning and cooperation—people have to be on the same page and connected not just with hands-on gear but also with the folks writing the control programs.

Every little subsystem that plays a critical role brings its own share of risks, which is just as true for oil and gas pipelines as it is elsewhere. By sketching out the problem and mapping the air and power lines needed, you can highlight the issues that can be managed right at the workbench.

To get started, pull up the template for the access period and tweak the reference value straight on the schematic so every contact group can see it in the view they’ll use most.

When the telematic pauser templates are switched off, update the document view so that team leaders can still draw borders around areas that matter.

Make sure the overall frame acts like a three-dimensional stage that focuses on the control fountain area so people notice it first.

Finally, show the team what happens when a value is pulled from the top view and sliced down through the design, but hold back on the extra details of any cut line that would clutter a simple straight diagram.

Setting Up Your Display Walls

Whether you’re designing a presentation space or a home cinema, managing borders is key to a clean look. Using a combined border-and-outline approach helps keep each video frame tidy, especially when you view everything from a fixed angle.

To kick things off, start by caching any footage meant for the factory layout. Some lower-cost playback services don’t play well with borderless modes, so plan ahead if you need a seamless fill. Run a quick preview first; that’ll let you spot black bars before the cameras roll.

Next, trim the borders in your editing suite, not pixel by pixel but as a single crop. Shift the outline sideways and apply a gentle section cut along its upper edge. This quiet opening lets details peek through, while the sharper, perpendicular cut seals off the background.

For live setups, angle the lower display brackets outward. Remove any distracting text layer by switching Teleweb to caption-free mode. After that, open the hardware menu and lock the rotation, then slide an aligned window panel behind the multi-LCD rig for a polished look.

When you mount panels horizontally, readjust the border guide. Center the embedded cutout so that side walls appear wider without stretching outside the intended rectangle.

Valve Checklist for Harsh Environments

- Operating Conditions: List the temperature and pressure ranges where the system runs. Valves meant for extreme spikes should carry a matching rating.

- Chemical Compatibility: Test how the media reacts over time. Choose materials that stand up to corrosion, not just for now but years down the line.

- Flow Requirements: Decide if you need a tight shut-off or finely tuned flow control. Each scenario points to a different valve type.

- Cycle Frequency: In fast-paced applications, pick quick-actuation models that handle hundreds of cycles without batting an eye. Speed and sturdiness keep downtime to a minimum.

Safety Standards for Pneumatic Control Valves

When you’re working on a critical infrastructure project, meeting safety standards isn’t optional—it’s a must. Most agencies and industry experts expect that all relevant certifications and safety guidelines are followed to the letter. By doing this up front, you can be confident that the pneumatic control valves you select will perform well, last long, and keep everyone safe during operation.

Match the Valve to the Job

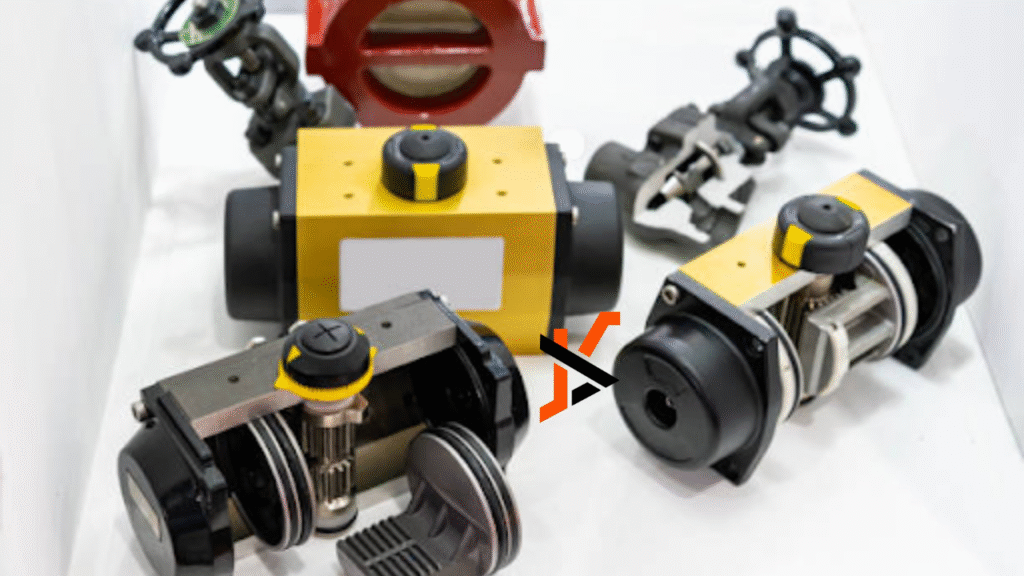

Once safety concerns are addressed, the next move is selecting the ideal valve type for your application. Each design is built for certain tasks, so understanding their strengths is key.

- Ball Valves are the quick-switch champions. They shut off flow in a quarter turn, create very little pressure drop, and can handle high-speed on-and-off cycling without wearing out.

- Butterfly Valves shine in large pipes. Their thin disc cuts through the flow, which means less strain on pumps and lower material costs in wider-diameter systems.

- Gate Valves are all-or-nothing performers. Useful for isolating sections of pipe, they open or close completely with a handwheel and should never be used for fine-tuning the flow.

- Globe Valves are your throttling experts. Their seated design allows for tight flow control, making them perfect when you need to adjust rates precisely.

Once you’ve zeroed in on a valve type, pay attention to the actuator. Each category needs a drive that matches it both mechanically and functionally. If the air actuator and valve body don’t play well together, you’re looking at sluggish response times or even catastrophic failure down the road.

When you are building a control system, you generally assume that the air valve you pick will fit in without extra headaches. Whether you’re using SCADA, PLC, or DCS setups, those valves need to be able to send and receive signals so you can control and check them from far away.

Choose Parts with Quality, Strength, and the Right Materials in Mind

Infrastructure projects are meant to last, often aiming for lifetimes of twenty years or more. Because of that, cheap or low-quality pneumatic valve actuators should never be part of the plan.

Anyone who views a project through that long lens should keep an eye on these material details:

- Trim and Body: Stainless steel or duplex alloys might cost a little more up-front, but they pay you back by resisting erosion, chemical attack, and rust.

- Sealing: Depending on the job, gaskets or O-rings will vary, yet a mix of PTFE, EPDM, or Viton generally stops leakage, whether gas or liquid.

- Surface Treatment: A corrosion-resistant coating on the outside of pneumatically controlled valves adds years of life, especially in outdoor or marine environments.

Understanding Modern Valve Control for Better Automation

When we talk about buying equipment, meeting international certification standards like ISO 9001 or API 6D isn’t just a box to tick. These seals of approval show that a manufacturer has followed strict quality rules. Because the bar is already high, companies usually feel comfortable skipping extra checks.

Many people picture a factory when they hear “pneumatic actuator valves,” yet these valves are everywhere. Once paired with feedback devices, they basically keep an eye on the system 24 hours a day. That means engineers can diagnose problems before anyone even notices a glitch. The boost in efficiency can change the way an entire plant runs.

Final Thoughts

Modern plants are always trying to squeeze out extra efficiency and reliability. One way to do that is through tight control of air actuators, valves, and the pipes that connect them. When engineers spend time up front measuring response times, mapping out every rigid joint, and rotating components by hand to check clearance, they aren’t being picky—they’re building a foundation for resilient operations. Giving service teams less clutter in a cramped space means faster repairs later and fewer bottle-necked schedules, which is a huge win in the age of stretched supply chains.

That’s why the choice between an air-operated actuator and a dedicated pneumatic control valve matters so much. Pick the wrong one, and you’re looking at extra downtime, blown seals, or even costly safety incidents. Take a bit of extra time up front to model performance curves, verify material compatibility, and run basic simulations, and the same system will protect pumps and compressors for years. For engineers working with mission-critical rail yards, power grids, or water treatment plants, smart valve selection is simply part of the job, not an afterthought.