Where the working conditions are highly stressful such as those in the industrial settings, temperatures have to be well controlled to optimize the durability and performance of the machines and electronics. Cooling fans are very essential in the management of heat and avoiding a breakdown of the systems. This article discusses different cooling fan solutions relevant to industrial applications with a view of understanding how this is of value to business-to-business organizations.

The Importance of Cooling Fans in Industrial Environments

Cooling fans are relevant where equipment and electronic equipment generate a lot of heat within industrial settings. Accurate cooling assists in controlling functional temperatures, avoiding temperatures that are too high and equipment breakdowns.

Key Benefits

1. Enhanced Performance: Cooling fans play an important role in controlling the temperature so that the performance of a device does not drop.

2. Prolonged Equipment Lifespan: Harsh heat may cause damage to the equipment and other components, thus reducing their lifespan; this is prevented by the use of insulators.

3. Reduced Downtime: Helps to reduce the probability of occurrence of overheating and consequent breakdown of equipment.

Types of Cooling Fans for Industrial Use

Different cooling fans are manufactured depending on the requirements of the highly stressed industries. Depending on the application, airflow that needs to be created, and the environment in which the fan will be used, the right fan is chosen.

Axial Fans

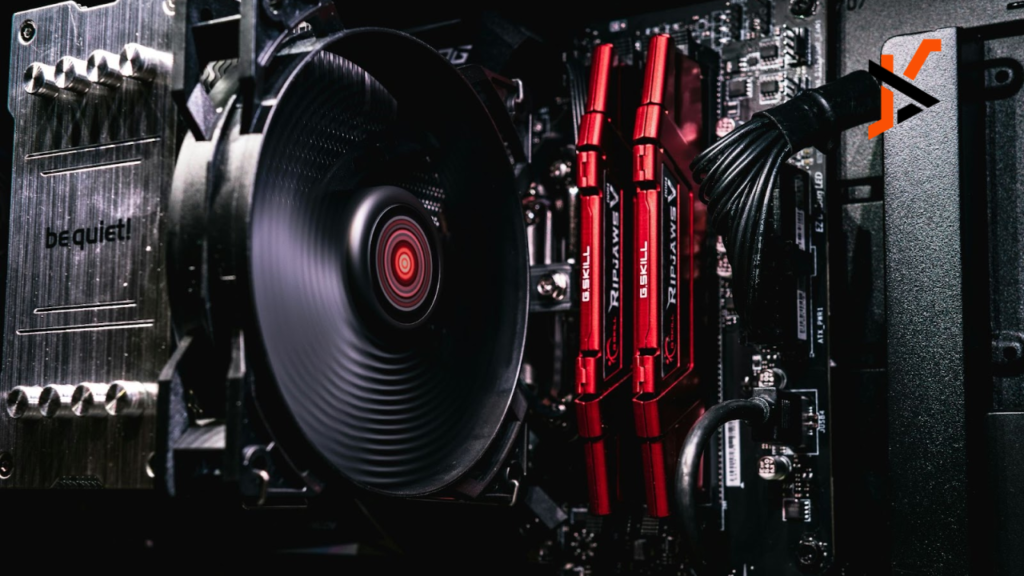

Axial fans are extensively used in the industrial processes because of its large air handling capacity.

1. Design: Equipment that has blades which causes the passage of air perpendicular to the axis of rotation.

2. Applications: Often used for general cooling in industries and other similar establishments.

3. Advantages: High airflow, efficient cooling, and rather low noise levels, though higher than in closed cases.

Centrif ugal Fans

Centrifugal fans are used when high pressure and directionality of air flow are needed.

1. Design: Operates on the use of a rotating impeller where it pulls in the air and then discharges it at a 90 degrees angle.

2. Applications: Subsequently efficient and effective in cooling high density electronic equipment and Machineries.

3. Advantages: High pressure, Mechanical robustness and cooling over long distances, all these are some of the advantages of silver halide crystals.

Compact Exhaust Fans

Mini exhaust fans are used where space is a limiting factor as they are small but are capable of cooling an area effectively.

1. Design: Portable, yet strong motors that are efficient in confined spaces.

2. Applications: They are applied in control panels, cabinets and other small industrial locations.

3. Advantages: Compact, effective at cooling, and dorin most cases, inaudible.

Innovations in Industrial Cooling Fan Solutions

Modern technologies in industries have enhanced the accomplishment of better and efficient cooling systems for stressed operations.

Smart Cooling Systems

Advanced sensors and control mechanisms are employed for the smart cooling where the cooling performance can be modified in terms of time.

1. Temperature Sensors: Oversee internal temperatures in real mode.

2. Automatic Adjustments: Regulate the speed of the fan and directions of the air flow based on the recorded temperature.

3. Energy Efficiency: Minimize power use when the centers are required to operate.

Supplier Cooling Fan Integration

This way, it is possible to buy cooling fans under favorable conditions and from a supplier who will provide precisely the industrial solutions needed for an existing application.

1. Customization: Companies can get fans that will work as per the specific operation they are designed for from the suppliers.

2. Quality Assurance: Prevent fans from operating below the set or industry standards or causing high power consumptions or inadequate heat rejection rates.

3. Technical Support: The opportunity to use the consultants‘ services and receive consultations for improving the equipment usage efficiency.

Liquid Cooling Solutions

Well, the fact is liquid cooling proves to be much more efficient than the air cooling concept when it comes to the rate of heat dissipation.

1. Design: Its primary function is to use a liquid coolant in order to extract as well as disperse heat.

2. Applications: Recommended for use where high power electronic equipment and devices are being used.

3. Advantages: Heat sink capability, noise level and adequate cooling in three high temperature conditions.

Best Practices for Cooling Fan Solutions

Policies, guidelines, and procedures involved in the identification of cooling fans and methods of installation, maintenance, and repairs of the equipment provide long-term efficiency.

Regular Maintenance

1. Inspections: cleanse often from dust, dirt, and abrasion by conducting routine examination checks.

2. Cleaning: Regularly clean the fans and vents to guarantee that there is no hindrance when it comes to air circulation.

3. Lubrication: Lubricate parts that move to reduce wear and tear because of the friction that such parts develop.

Proper Installation

1. Positioning: A fan must be placed to blow air toward a specific location, either downward or toward the wall.

2. Mounting: This should prepare for vibrations and noise production by the fans by ensuring they are properly fixed.

3. Connections: Inspect connectors for tightness and signs of corrosion such as discoloration of the connector.

Monitoring and Control

1. Temperature Sensors: In use internal temperatures should be checked by temperature sensors.

2. Control Systems: Sponsorize direct control mechanisms to prompt variation of fan speed in relation to cooling demands.

3. Alerts: It is necessary to set up alarms to higher temperatures not to reach critical levels.

Small exhaust fans are critical in ensuring that industrial compact spaces that are limited in terms of the available floor space achieve the set optimal conditions for temperature. These fans can be used in control panels, cabinets, and other places where they do not congest much space but give adequate air circulation.

Future Trends in Industrial Cooling Fan Solutions

Thus the future of industrial cooling fan solutions presents an increase in performance, efficiency, and ease of use, as another step in a progressive plan.

Energy-Efficient Designs

Future cooling fans will have optimized energy consumption to cut on the costs of operating and polluting the environment.

1. Low Power Consumption: It will also mean that fans to be used will be designed to consume as little power as possible and at the same time produce as much cooling effect as possible.

2. Sustainable Materials: Recyclable and Sustainable materials have to be implemented in the construction of the fans.

3. Enhanced Control: The smart control systems to cool that would be accurate and efficient.

AI and Machine Learning

AI and ML technology is being incorporated into cooling systems; then the cooling needs can be predicted and tackled on an as-needed basis.

1. Predictive Cooling: AI solutions that assess when the temperature is going to rise or fall and regulate cooling in anticipation.

2. Adaptive Control: Programmed intelligent systems that adapt the cooling to the usage of the buildings.

Integration with IoT

The IoT especially has been identified to be vital in the handling of the future of industrial cooling.

1. Connectivity: Fans shall be integrated into the IoT networks for monitoring and controlling their operations.

2. Data Analytics: Proactive analysis of data that helps in the determination of when equipment will require maintenance, and how to bring out the best in the equipment.

3. Automation: Fully automatic control as a result of continuously received data and existing conditions.

Cooling fan solutions play a crucial role in avoiding equipment degradation in high-stress industries, hence the need to invest in the best solutions. Regarding cooling, companies use highly efficient fans to cool their machinery while following recommended practices to avoid equipment heat-related breakdowns.

Starting from the small size exhaust fans to the smart cooling systems or the liquid cooling solutions, the improvements in cooling fans give excellent and efficient thermal management solutions to many sectors. Working with a credible cooling fan manufacturer enables one to acquire standardized solutions that fit the exact needs of the various industries.

In B2B business, proper cooling fan solutions help control the performance, time-saving, and equipment durability or life span. Thus, knowing the trends in the future and using the innovations that exist in the cooling fan systems, one can confidently state that business systems will be effective and reliable.