Manufacturers across industries rely on plastic components to keep production efficient and cost-effective. Be it automotive interiors or consumer appliances, plastic parts serve as the backbone of modern products. Creating high-quality plastic parts can turn into a complicated process without the right expertise.

Professional injection molders simplify the entire plastic part manufacturing process through precision, design optimization, and consistent results. Their goal is simple. Make plastic part production easier, faster, and more dependable for companies that rely on these parts.

Design Simplification through Expert Guidance

An experienced injection molder helps a company refine part designs to remove unnecessary complexities. The process starts with a review of the 3D model or concept shared by the client. The molder studies each feature, edge, and thickness to identify areas that create molding issues. Through design advice, the molder suggests changes that improve manufacturability and material flow. This step prevents multiple prototypes or tooling adjustments later.

Molders ensure proper wall thickness, gate location, and draft angles, which allow smooth part release from the mold. These details create consistent production and reduce defects. A simple design reduces cycle time and production cost. A reliable molder acts as an extension of the client’s design team, ensuring parts are functional and easy to mold. Early collaboration saves time and reduces production stress.

Material Selection Made Easier

Choosing the right material is a crucial step in plastic part manufacturing. An injection molder knows how different resins behave under heat, pressure, and flow conditions. Their expertise guides companies toward materials that balance strength, flexibility, and cost. Many projects fail when the chosen material does not suit the application.

Molders advise clients on thermoplastics such as ABS, nylon, polypropylene, and polycarbonate. They suggest resin blends or additives that enhance performance. A part used outdoors may require UV-resistant material, while a medical component needs biocompatible resin. Each choice affects cost, durability, and molding cycles.

Precision Tooling for Consistent Output

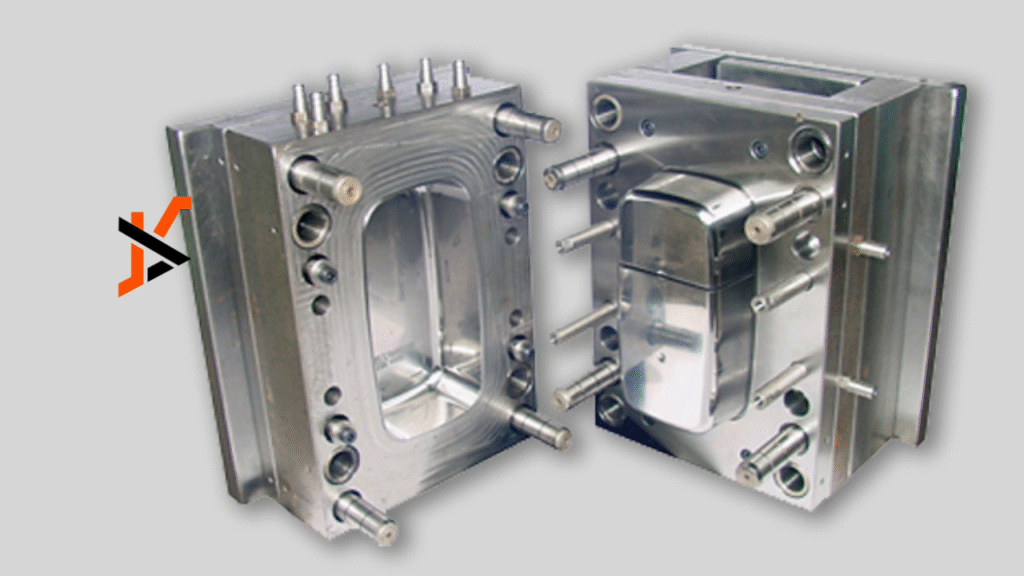

Tooling forms the foundation of every molded part. A well-designed mold ensures consistent shape, surface finish, and dimensions across thousands of parts. Injection molders invest in advanced tool-making techniques to achieve precision. CNC machines and EDM technology create molds with high accuracy.

Each tool matches the part geometry and production volume. Large-scale runs use hardened steel molds that last longer. Smaller batches use aluminum molds as a cost-effective option. Regular maintenance of molds ensures smooth cycles and defect-free production. This focus on detail simplifies manufacturing for companies. They receive uniform parts every run, reducing waste and production delays.

Process Optimization for Faster Production

Injection molders streamline production steps to reduce time and cost. They adjust each stage, from mold setup to cycle parameters, to achieve higher output with minimal downtime. Automation plays a key role. Robotic systems handle tasks such as part removal and assembly, increasing efficiency.

Molders track key factors such as pressure, temperature, and cooling rate to maintain stable cycles. Small adjustments during early runs create long-term production stability. Once the process stabilizes, parameters are documented for consistent replication. This approach eliminates interruptions during production. Companies gain shorter lead times and predictable schedules. Process optimization ensures each production run maintains high standards.

How Injection Molders Simplify Operations

- Single-source production: Companies get design, tooling, and molding under one roof, saving coordination effort.

- Prototyping support: Molders provide sample runs to verify part quality before mass production.

- Material traceability: Each batch receives tracking for quality assurance and compliance.

- Reduced waste: Efficient molding practices minimize excess material and scrap.

- Automation integration: Robots and sensors maintain accuracy and consistency.

- Quality inspections: Dimensional checks and visual inspections confirm part compliance.

- Inventory management: Some molders store finished parts and ship on demand.

- Technical consultation: Clients receive advice on cost-saving design and tooling choices.

- Process documentation: Each job includes detailed records for future reference.

- Sustainability focus: Many molders use recycled resins and energy-efficient equipment.

Each point contributes to smoother production. Companies that partner with molders offering complete services gain better control over timelines and results.

Quality Control That Prevents Rework

Quality assurance ensures each plastic part meets the specification. Injection molders follow strict quality checks throughout production. Material inspection and final part validation receive careful attention. Molders use precision tools such as coordinate measuring machines (CMMs) and vision systems to confirm part dimensions.

Early detection of defects prevents wasted time and materials. Regular mold maintenance and calibration maintain consistency. Continuous monitoring keeps tolerances tight over long production runs. Companies benefit from fewer product returns and smoother assembly operations. Consistent quality reduces costs related to rework and warranty claims. Reliable quality control simplifies operations and keeps production efficient.

Injection molders play a key role in simplifying plastic part manufacturing for companies. A dependable molder acts as a strategic partner, helping companies maintain efficiency and quality from start to finish. This collaboration transforms complex manufacturing requirements into a smooth and predictable process.