A Practical Guide for Facility Managers, Safety Engineers, and Procurement Teams

Introduction

Volatile Organic Compounds (VOCs) are a major hazard in chemical storage areas. From off-gassing drums to minor valve leaks, VOCs can accumulate to dangerous levels—creating fire risk, regulatory violations, and health threats. Selecting the right VOC gas detector is not just about specifications—it’s a strategic decision that impacts compliance, insurance liability, and operational uptime.

With so many models on the market—PID sensors, single-gas vs. multi-gas, analog vs. digital output—choosing the right unit can be overwhelming. This guide simplifies the decision-making process for professionals tasked with safety compliance and risk control.

Why VOC Gas Detection Matters

VOCs are organic chemicals that easily vaporize. Many are harmful even at low concentrations. Unlike explosive gas detectors (which trigger based on LEL), VOC detectors—often based on PID (photoionization detection)—track low-level chemical vapors like benzene, toluene, acetone, and xylene.

In storage environments, VOCs can be released through:

- Leaky containers and solvent drums

- Chemical transfer stations and pipelines

- Valve vents and pump enclosures

- Ambient evaporation in enclosed spaces

Even when not explosive, these vapors can exceed OSHA Permissible Exposure Limits or trigger EPA reporting thresholds. Continuous detection ensures early warnings and reduces compliance risk.

Regulatory Snapshot: OSHA & EPA Compliance

- OSHA: Exposure limits for individual VOCs range from 5–50 ppm. Facilities may be required to monitor worker exposure zones.

- EPA: VOC emissions over certain thresholds may trigger reporting, especially in hazardous waste or manufacturing sites.

- In some cases, facilities are mandated to use fixed detectors linked to alarms and exhaust systems.

To comply, VOC monitors should:

- Support visual + audible alarms

- Log calibration and maintenance activities

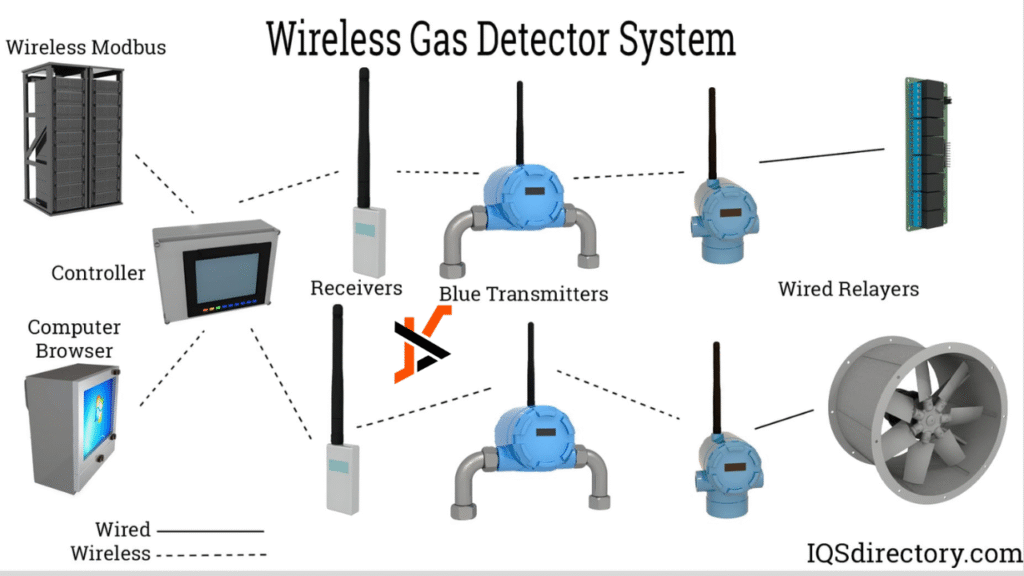

- Preferably integrate with SCADA or BMS systems

Types of VOC Detection Solutions

Your selection depends on gas types, risk concentration, and installation environment. Here’s a breakdown:

1. Single VOC Monitor (PID-based)

Recommended for:

- Labs, cleanrooms, R&D spaces

- Sites focused solely on VOC emissions

- High-accuracy compliance monitoring

Benefits:

- Detects VOCs down to 0.1 ppm

- Less affected by combustible/toxic gas interference

- Ideal for targeted TVOC or emission tracking

Limitations:

- Does not detect CO, CH₄, or O₂—other sensors may be required in multi-risk zones

Recommended specs:

- PID sensor with 10.6 eV lamp

- 0–1000 ppm range (or higher)

- IP65-rated housing

- 4–20 mA + Modbus output; optional data logging

- Wall or duct-mounted

2. Multi-Gas Detector with VOC Module

Recommended for:

- Tank farms, warehouses, solvent handling areas

- Confined spaces with multiple gas risks

- Facilities moving toward full digital safety integration

Benefits:

- One unit detects VOC + CO + O₂ + H₂S + LEL

- Reduces cabling and number of devices

- Compatible with SCADA / DCS

- Built-in diagnostics, remote calibration

Recommended specs:

- PID VOC range: 0–1000 ppm or 0–5000 ppm

- Additional sensors: CH₄, CO, O₂, H₂S

- IP65 or better housing

- Modbus RTU + 4–20 mA output

- Local alarms with optional relays

Best for: Modern facilities looking to future-proof gas safety with integrated hardware.

3. Dedicated VOC Gas Detector (Single-Gas) (e.g., CH₄, Benzene)

Recommended for:

- Sites with clearly defined, single-gas hazards

- Pipeline monitoring, point-source detection

- Cost-sensitive applications requiring scalable deployment

Specs:

- Fixed gas (e.g., methane, benzene, acetone)

- Range: 0–100% LEL or 0–1000 ppm

- IP65 housing

- 4–20 mA output + optional alarm relay

How to Decide If You’re Not Sure What VOCs Are Present

If your site handles mixed chemicals or solvents, you don’t need a sensor for every compound.

- Use a PID VOC detector to measure total VOC levels (TVOC) in ppm

- Only use compound-specific sensors (e.g., benzene-only) if required by regulations or for process control

Price Reference (International Market)

| Type | Price Range (USD) | Application |

| Single PID VOC detector | $1,100 – $5,700 | High-precision VOC concentration monitoring |

| Single-gas VOC detector (e.g., CH₄) | $900 – $2,500 | Specific risk detection, low-cost deployments |

| Multi-gas detector with VOC | $2,100 – $5,400 | All-in-one industrial zone safety monitoring |

| Portable multi-gas detector | $1,600 – $4,400 | For walkaround inspections and confined spaces |

While Single PID VOC detectors offer high precision, they tend to be more expensive and focus solely on VOCs.

Multi-gas detectors with VOC modules are generally more cost-effective, providing broader gas coverage in one device.

Note: Entry-level single-gas detectors (e.g., for methane) typically range from $300 to $800 for basic safety monitoring.

However, industrial-grade fixed or portable models with advanced sensors, broader measurement ranges (e.g., 0–100% VOL), and integrated alarms or outputs may exceed $2,000 depending on specifications.

Example Configurations Based on Real-World Needs

To match varying risk profiles in modern industrial settings, many facilities choose integrated or compound-specific gas detection strategies. Below are practical configurations aligned with real-world deployment:

Fixed Wall-Mounted Multi-Gas Detectors with VOC Modules

Ideal for tank farms, solvent warehouses, and processing zones where multiple hazards coexist (VOC, CO, O₂, LEL, H₂S).

- Combines PID VOC sensor + toxic + flammable gas sensors

- Compatible with SCADA/DCS (4–20 mA, Modbus)

- IP-rated housing with optional local alarms and relays

- Streamlines installation by reducing total sensor count

- Estimated cost: $1,800 – $2,800 USD

This is our recommended solution for most industrial sites with complex chemical inventories.

Dedicated Gas Detectors (e.g., Benzene, Methane, Ammonia)

Used in applications with well-defined hazards or compliance requirements (e.g., benzene monitoring per OSHA Subpart Z).

- Factory-calibrated for one gas

- Quick response time and rugged design

- Ideal for pipelines, storage valves, and pump areas

- Lower-cost solution when only one gas is present

- Estimated cost: $900 – $2,500 USD

These devices offer targeted accuracy and scalable deployment across distributed risk points.

Portable Multi-Gas Monitors (Optional)

Useful for walkaround inspections, confined space entry, or hot-spot validation.

- Detects 4–5 gases including VOCs

- Logging, alarms, and calibration tracking

- Complements fixed installations for full coverage

- Retail price: $1600 – $4,400 USD

Installation and Maintenance Tips

- Placement: Install near leak points, not ceilings. Use duct models for exhaust zones.

- Calibration: Perform monthly bump tests; calibrate every 6 months.

- Alarm Testing: Check both local and SCADA-based alerts monthly.

- Environment: Use humidity-compensated PID models in high-moisture areas.

Frequently Asked Questions

Q: Can one PID sensor detect multiple VOCs?

Yes. PID sensors respond to a broad range of VOCs and report total concentration (TVOC), which is ideal for general monitoring.

Q: Do VOC sensors replace combustible gas detectors?

No. They detect non-explosive vapors. You still need LEL sensors for explosion risk zones.

Q: What if I only need a basic alarm for safety?

A fixed PID VOC unit with analog output and relay can meet most safety use cases at lower cost than full SCADA integration.

Conclusion

To ensure safe chemical storage and meet regulatory demands:

- Choose a PID-based detector suited to your VOC exposure risks

- Use multi-gas models if your site has CO, LEL, or O₂ risks

- Verify signal compatibility with your control system

- Maintain units regularly for accuracy and audit readiness

Start with a fixed wall-mounted detector for general VOC monitoring. For complex zones, use pipeline models or integrated multi-gas systems. This approach balances compliance, cost, and operational safety.