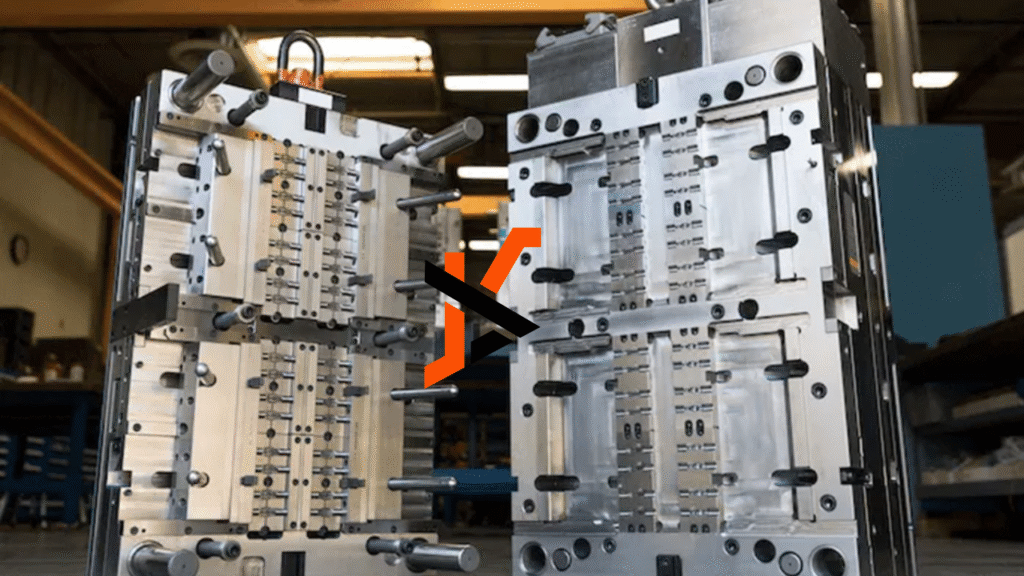

Plastic molds are essential in modern manufacturing, serving industries such as automotive, electronics, medical devices, and packaging. The quality and precision of these molds directly impact the efficiency and durability of the end products. Sourcing plastic molds from China has become a popular choice due to cost-effectiveness, advanced manufacturing capabilities, and a vast supplier base. However, there are concerns such as quality assurance, reliability, logistics, and intellectual property (IP) protection. In this article, we’ll explore how to effectively source plastic molds from China, ensuring that you get high-quality products while managing the complexities of the process.

Understanding the Plastic Mold Industry in China

China has established itself as a global leader in plastic mold manufacturing, thanks to its competitive pricing, skilled labor, and cutting-edge technology. Let’s break down the key factors that make China the top choice for sourcing plastic molds.

Types of Plastic Molds

There are several types of plastic molds, each designed for specific manufacturing processes:

- Injection Molds: Used for producing precise plastic parts through injection molding, commonly used in automotive, electronics, and consumer goods industries.

- Blow Molds: Ideal for creating hollow plastic products, such as bottles, containers, and tanks.

- Extrusion Molds: Used for continuous processes, such as making pipes, sheets, and films.

- Compression Molds: Primarily used for thermoset plastics, suitable for making large, complex parts.

Why China Leads in Plastic Molds

China is known for:

- Competitive Pricing: Due to low labor costs and high-volume production capabilities, China can offer significantly lower prices compared to other regions.

- Skilled Labor: The country has developed a pool of highly skilled professionals specializing in mold design and manufacturing.

- High Production Capacity: Chinese factories have the infrastructure to handle large-scale production runs, ensuring timely deliveries.

- Technological Advancements: With increasing investments in machinery and automation, Chinese factories are adopting the latest technology to improve mold precision and efficiency.

Key Mold Manufacturing Regions

China’s major mold manufacturing hubs include:

- Guangdong Province (Shenzhen, Dongguan): Known for its well-established mold-making industry, offering a wide range of molds and tooling options.

- Zhejiang Province (Ningbo): Famous for its advanced machinery and technology, particularly in precision molds.

- Jiangsu Province (Suzhou): A hub for high-quality plastic mold production, particularly in industries like automotive and medical.

Where to Find Reliable Plastic Mold Manufacturers

Finding a reliable plastic mold manufacturer in China requires thorough research and strategic sourcing. Here are some of the best ways to connect with reputable suppliers:

Online Sourcing Platforms

Platforms like Alibaba, Made-in-China, and Global Sources are excellent starting points. These platforms provide a wide range of supplier listings, allowing you to review their products, read customer feedback, and request quotes. However, always verify the credibility of the supplier through reviews and ratings.

Industry Trade Shows & Exhibitions

Attending trade shows such as ChinaPlas, Canton Fair, and DMP Die & Mould Expo can provide an excellent opportunity to meet manufacturers face-to-face. You can inspect the products directly, evaluate the quality, and engage in real-time discussions about your requirements.

Manufacturers’ Official Websites

A reputable plastic mold factory often has well-designed websites showcasing their capabilities, case studies, and certifications. Direct communication with manufacturers allows for better negotiation and custom solutions tailored to your specific needs.

Third-Party Sourcing Agents

If you’re unfamiliar with the Chinese manufacturing landscape, third-party sourcing agents can help by verifying the legitimacy of factories, negotiating prices, and managing logistics.

How to Evaluate and Select the Right Supplier

When selecting a supplier, it’s crucial to assess more than just price. Consider the following factors to ensure you partner with the right manufacturer:

Key Factors to Consider

- Certifications: Look for ISO certifications, such as ISO 9001 (general quality), IATF 16949 (automotive), and ISO 13485 (medical). These certifications indicate that the manufacturer follows internationally recognized quality standards.

- Production Capabilities: A reliable supplier should offer advanced manufacturing capabilities like CNC machining, EDM processing, and mold flow analysis to ensure precise, high-quality molds.

- Experience & Client Portfolio: Evaluate the supplier’s years in business, past projects, and customer feedback. Experienced manufacturers are more likely to meet your expectations.

- Material Quality: The type of steel used for the molds, such as P20, H13, and S136, directly affects mold durability and performance. Ensure the supplier uses high-quality materials.

Factory Audits

Before placing a large order, request a factory visit or conduct an audit. This will help you inspect the facilities, machinery, and quality control processes.

Price Negotiation and Payment Terms

Mold prices vary based on several factors, including complexity, material selection, and production volume. To negotiate effectively:

- Compare Multiple Quotes: Obtain quotes from several suppliers to gauge price competitiveness.

- Inquire About Bulk Discounts: If you plan to place regular orders, discuss volume-based discounts.

- Understand Payment Terms: Common terms include a 30% deposit, 40% during production, and 30% upon completion. For large transactions, consider using escrow services or Letters of Credit for added security.

Quality Control and Production Monitoring

Maintaining consistent quality is essential. Work with your supplier to ensure the following:

- First Article Inspection (FAI): Conduct an FAI to verify that the first mold meets your specifications.

- In-Process Quality Control: Monitor production at various stages to catch potential issues early.

- Final Testing: Conduct mold trials with different plastic materials to assess mold durability and performance.

- Third-Party Quality Assurance: Consider hiring third-party QC services such as SGS, TÜV, or BV for independent inspections.

Logistics & Shipping: Getting Your Molds Safely

Once the molds are ready, focus on logistics to ensure safe delivery:

- Shipping Methods: Choose between air freight (fast but expensive) and sea freight (cost-effective for large orders).

- Customs & Import Regulations: Work with a freight forwarder to handle customs duties, taxes, and documentation.

- Packaging: Ensure that molds are packed securely using anti-rust coatings, shock-absorbent materials, and wooden crates.

Intellectual Property Protection When Sourcing in China

Protecting your intellectual property (IP) is crucial when sourcing molds in China. Here’s how to safeguard your designs:

- Non-Disclosure Agreements (NDAs): Use NDAs to prevent unauthorized sharing of your designs.

- Register IP in China: To avoid counterfeiting, consider registering your patents and trademarks in China.

- Work with Reputable Manufacturers: Choose suppliers with a track record of respecting IP rights and ensuring confidentiality.

Conclusion

Sourcing plastic molds from China offers significant cost advantages, but the process requires careful attention to detail. By understanding the industry, evaluating suppliers based on quality and capabilities, negotiating prices, and ensuring IP protection, you can mitigate risks and establish a successful partnership. Start with small test orders, and as you build trust with your suppliers, gradually scale up your operations for long-term success.