Learning 3D printing opens doors if you want to prototype a product, fix a broken part at home, or build a small business. In Australia, the technology is no longer niche; hobbyists, students, and engineers utilise desktop machines and industrial services daily.

This guide provides a clear, practical pathway from complete beginner to confident maker, with no jargon-heavy detours, just the steps that work.

What is 3D Printing?

3D printing, also known as additive manufacturing, creates objects piece by piece from a digital design. It’s a fascinating process that allows for detailed and customised builds, and software such as OrcaSlicer plays a crucial role here by turning digital models into accurate layer-by-layer instructions for the printer.

There are several mainstream systems you’ll meet early on: fused filament fabrication (FDM), resin-based systems like stereolithography (SLA), and powder-based approaches such as SLS. Each has trade-offs in terms of price, detail, and material choices, so understanding the main families helps you select the right tools for your goals.

Hardware, Software, and Vocabulary

Essential hardware

For beginners, affordable FDM printers are a friendly entry point; they use plastic filament and are relatively forgiving. If your priority is fine detail or smooth surfaces (for jewellery or dental models), you’ll encounter resin SLA machines later.

Industrial methods, such as SLS and metal printing, are powerful but are usually accessed through service providers rather than home machines.

Essential software

You’ll need two software skills: CAD (creating digital models) and slicing (preparing files for the printer). Start with beginner-friendly CAD tools, such as TinkerCAD or the free version of Fusion 360, and a slicer like Ultimaker Cura or PrusaSlicer to convert your models to G-code. Learn to recognise common file types (STL, OBJ) and keep a well-organised library of test files as you learn.

Key Vocabulary

- Layer height, infill, supports, nozzle diameter, and bed adhesion. Get familiar with these early.

- Safety: Resins and fine powders require careful handling. Always ventilate and use gloves when necessary.

A Practical Learning Pathway

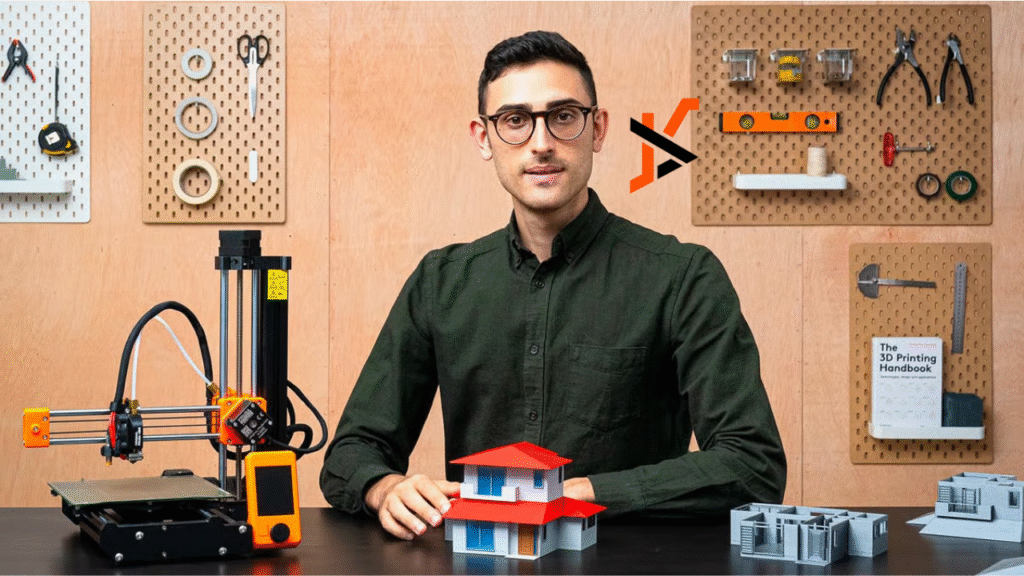

Take a moment to explore this step-by-step learning path for 3D printing. It’s a friendly guide to help you learn the process easily and confidently.

Step 1: Learn the basics of CAD

Spend time modelling simple shapes, then move to assemblies and constrained sketches. Focus on designing parts that print well, considering overhangs, wall thickness, and how print orientation affects strength.

Step 2: Master slicing and calibration

Print calibration cubes, temperature towers, and retraction tests. These simple prints teach how temperature, print speed, and cooling interact. Write down settings that work for each filament brand, PLA, PETG, and ABS behave differently.

Step 3: First projects and finishing

Start with practical, small projects: phone stands, replacement knobs, or jigs. Learn the techniques of sanding, priming, and painting for clean, professional results. For resin prints, practice washing and curing safely.

Step 4: Troubleshooting and maintenance

Maintain a checklist: clean the nozzle, level the bed, update firmware, and replace worn parts. When prints fail, isolate the variables, such as slicer settings, filament quality, or mechanical issues, and change one thing at a time.

Moving from Hobbyist to Professional

Design for additive manufacturing

To go pro, you’ll need to design specifically for 3D printing: minimise supports, design interlocking parts, and use lattice or honeycomb infill for strength without weight. Learn to specify tolerances and post-processing steps in job quotes.

Quality, materials, and scale

Invest in measuring tools (callipers) and sample workflows for different materials. If you plan small-batch production, consider using print farms or partnering with local service providers for faster turnaround times.

Business basics

If you want to monetise your skills, catalogue service offerings (rapid prototyping, custom parts, small runs), price by material and machine time, and build a portfolio of reliable case studies. Professional work demands version control, thorough documentation, and communication with clients.

Where to Learn and Get Local Help in Australia

Hands-on learning accelerates progress. Look for makerspaces, university workshops, and local print services that offer guidance and print-for-hire options. If you’re local to Western Australia, there are established service providers offering rapid prototyping and materials expertise for makers and designers.

For designers and businesses in Queensland, 3D printing in Brisbane is often managed by local CAD and printing specialists. If you require a quick quote and CAD support, reach out to CAD Deziners for advice on production-ready files.

Practical Safety and Sustainability Tips

Always follow the manufacturer’s safety instructions. Recycle failed prints where possible (some filaments can be shredded and re-extruded), and choose lower-energy workflows for routine prototyping.

FAQs

Q1: What is the easiest 3D printer for beginners?

Look for a reliable, well-documented FDM printer with a heated bed and good community support; these make learning quicker and troubleshooting easier.

Q2: Do I need to learn CAD to get started with printing?

No, you can print models from online repositories. But to progress, CAD skills are essential if you want to design custom parts.

Q3: Which materials should a beginner try first?

PLA is forgiving, has a mild smell, and prints at low temperatures; it’s a great starting material.

Q4: How long do prints take?

It varies widely: a small part may take 15 to 30 minutes, while larger, detailed prints can run for many hours. Plan print time into your workflow.

Q5: Can 3D printing be a viable business?

Yes, for prototyping, custom parts, short-run manufacturing, and specialised niches. Success depends on quality, turnaround time, and effective client communication.

Q6: How do I improve surface finish?

Use finer layer heights, slow the print speed for outer shells, and apply sanding, priming, and finishing techniques appropriate to the material.

Q7: Are there local courses or meetups I can join?

Makerspaces, TAFE courses, and local university workshops often offer beginner classes; check local listings and community groups for details.

Q8: When should I use a service provider instead of printing myself?

For large volumes, metal parts, very high precision, or specialised materials, consider using a professional service for improved speed, reliability, and materials expertise.

Final Thoughts

Moving from novice to pro in 3D printing is a steady and rewarding process: learn CAD, master your slicer, practise calibration, and iterate on real-world projects. For those seeking expert guidance and professional support, CAD Deziners offers reliable services for 3D printing in Perth, ensuring you have the right resources and materials to grow your skills.

Stay curious, document what works, and you’ll find the skill pays off, if it’s for creative fulfilment, solving everyday problems, or building a business.