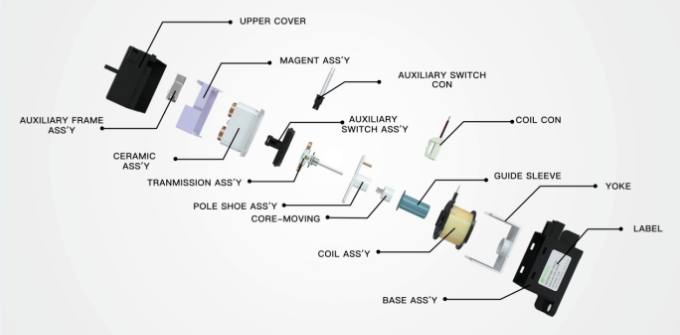

High-voltage direct current (HVDC) systems have become the backbone of modern electric vehicles, renewable energy infrastructure, and industrial power distribution networks. At the heart of these systems lie HVDC contactors—critical switching components that must perform flawlessly under extreme electrical and thermal stress. The reliability of these devices depends fundamentally on the materials used in their construction, from advanced ceramics to specialized metal alloys.

The evolution of HVDC contactor technology reflects decades of materials science innovation and engineering refinement. Unlike traditional AC contactors, HVDC contactors must handle significantly higher electrical stress due to the absence of natural current zero-crossings in DC systems. This fundamental challenge has driven manufacturers to develop sophisticated material combinations that can withstand voltages exceeding 1000V while maintaining operational reliability over millions of switching cycles. Modern applications in electric vehicles and energy storage systems demand contactors that are not only electrically robust but also compact, lightweight, and thermally efficient. The automotive industry’s push toward 800V and even 1000V battery systems has further intensified the need for advanced materials that can handle these elevated voltage levels without compromising safety or longevity.

The selection of appropriate materials begins with understanding the specific failure mechanisms in HVDC switching applications. High-voltage DC relays and contactors face unique challenges including arc erosion, contact welding, insulation breakdown, and thermal degradation. Each component—from the contact surfaces to the housing—requires materials engineered to address these specific stress factors while contributing to overall system performance. The interdependence of these materials creates a complex design space where optimization in one area cannot compromise performance in another.

Contact Materials: The Critical Interface

The contact surfaces represent the most challenging material engineering problem in HVDC contactors. When contacts separate under load, they must extinguish powerful DC arcs that can reach temperatures exceeding 6000°C within microseconds. The ideal contact material must balance several competing properties that often work against each other from a metallurgical perspective:

· High electrical conductivity to minimize resistive heating during normal operation and reduce voltage drop

· Arc erosion resistance to maintain contact geometry and surface quality over extended service life

· Resistance to welding under high current and temperature conditions that occur during fault scenarios

· Mechanical stability to withstand repeated impact forces during closing operations without deformation

· Chemical stability to resist oxidation and contamination in various operating environments

Silver-based alloys have emerged as the dominant solution for high-performance applications, with carefully controlled additions of cadmium oxide, tin oxide, or nickel providing enhanced arc resistance. Advanced formulations incorporate tungsten or molybdenum particles dispersed throughout the silver matrix to improve erosion resistance while maintaining acceptable conductivity levels above 85% IACS (International Annealed Copper Standard). Some manufacturers employ composite materials with silver matrices reinforced by refractory metal phases, achieving erosion rates below 1 mg per 10,000 operations even at current levels exceeding 100A.

Recent developments have focused on cadmium-free alternatives due to environmental regulations. Silver-tin-oxide (AgSnO2) composites have gained prominence, offering comparable performance to traditional silver-cadmium-oxide materials while meeting RoHS compliance requirements. The microstructure of these materials requires precise control during manufacturing, with powder metallurgy techniques ensuring uniform distribution of oxide particles throughout the silver matrix.

Ceramic Insulators: The Unsung Heroes

While contact materials receive considerable attention in technical literature, the ceramic components in HVDC contactors play an equally vital role in system reliability and longevity. These insulators must maintain their dielectric properties across extreme temperature ranges—from -40°C to +125°C or higher—while resisting electrical tracking, flashover, and mechanical stress from thermal expansion.

Alumina ceramics (Al₂O₃) dominate high-voltage applications due to their exceptional combination of electrical insulation, mechanical strength, thermal conductivity, and cost-effectiveness. High-purity alumina (>95% Al₂O₃) provides dielectric strength exceeding 15 kV/mm while maintaining structural integrity at temperatures beyond 300°C. The material’s thermal conductivity of approximately 25 W/m·K facilitates heat dissipation from arc zones, preventing localized hotspots that could compromise insulation performance or lead to thermal runaway conditions.

For applications requiring even higher performance parameters, manufacturers turn to aluminum nitride (AlN) and zirconia-toughened alumina (ZTA). These advanced ceramics offer substantial improvements over standard alumina:

· Superior thermal conductivity (170 W/m·K for AlN versus 25 W/m·K for alumina) enabling better thermal management

· Enhanced mechanical strength exceeding 400 MPa flexural strength and improved fracture toughness

· Improved resistance to thermal shock, critical for rapid switching cycles

· Lower dielectric loss tangent at high frequencies, important for minimizing losses in fast-switching applications

· Better resistance to high-voltage creep and long-term degradation mechanisms

The selection between these ceramic materials involves trade-offs between performance, cost, and manufacturing complexity. While aluminum nitride offers superior thermal properties, its higher cost and more demanding processing requirements limit its use to premium applications where thermal management is critical.

Alloy Engineering for Structural Components

Beyond contacts and insulators, the structural components of HVDC contactors require careful material selection to ensure mechanical reliability and electrical performance. Current-carrying terminals typically employ copper alloys with controlled additions of chromium, zirconium, or beryllium to achieve high conductivity combined with mechanical strength and creep resistance at elevated temperatures. These copper-chromium-zirconium (CuCrZr) alloys maintain conductivity above 80% IACS while offering yield strengths exceeding 400 MPa after appropriate heat treatment.

The manufacturing process for these terminal components often involves complex forming operations followed by precipitation hardening heat treatments. This processing sequence develops fine precipitates that strengthen the alloy matrix without significantly compromising electrical conductivity—a delicate balance that requires precise control of composition and thermal processing parameters.

Magnetic circuit components utilize specialized soft magnetic alloys designed for rapid response and minimal energy loss during actuation. Silicon steel laminations with controlled silicon content (typically 3-4% Si) reduce eddy current losses while maintaining adequate magnetic flux density. The lamination thickness—often between 0.35-0.50 mm—represents an optimization between mechanical handling considerations and electromagnetic performance.

For compact actuator designs requiring maximum force density, cobalt-iron alloys provide enhanced magnetic saturation levels approaching 2.4 Tesla compared to 2.0 Tesla for conventional silicon steel. These high-performance magnetic materials enable smaller, lighter actuator assemblies—a critical advantage in space-constrained applications such as electric vehicles.

Arc Quenching and Housing Materials

The housing materials for HVDC contactors must provide mechanical protection, electromagnetic shielding, and in some designs, contribute to arc quenching. Modern designs increasingly employ engineering polymers reinforced with glass or carbon fibers to achieve high strength-to-weight ratios. These composite materials must maintain dimensional stability across wide temperature ranges while resisting degradation from arc byproducts, ozone, and environmental contaminants.

Arc chutes and quenching plates often utilize steel alloys with specialized coatings or ceramic components arranged to divide and cool the arc during interruption. The magnetic field shaping provided by these materials guides the arc away from critical components and into cooling zones where thermal dissipation can occur rapidly.

The Future of Contactor Materials

Emerging research explores several promising directions for next-generation contactor materials. Nanomaterial-enhanced composites incorporating carbon nanotubes or graphene show potential for improved electrical and thermal properties. Additive manufacturing techniques enable complex geometries and graded material compositions previously impossible with conventional manufacturing methods.

Ceramic matrix composites (CMCs) combining oxide or nitride matrices with reinforcing fibers offer exceptional high-temperature performance. These materials could enable contactors operating at elevated temperatures without active cooling, simplifying system design and improving reliability.