Figure 1: Strategic design and manufacturing choices can significantly reduce rapid prototyping costs without sacrificing quality.

Introduction

Does Your Rapid Prototyping Budget Feel Like a Black Hole?

You’re not alone. In today’s race to innovate, the pressure to iterate faster and cheaper is relentless. But if you’re still trying to cut costs by haggling over material prices or shopping for the lowest hourly machine rate, you’re fighting the wrong battle. The real savings—often up to 40% per part—aren’t found in spreadsheets; they’re baked into your design and manufacturing strategy.

This article cuts through the noise to give you five actionable, data-backed strategies that top engineers use to slash CNC machining costs dramatically. The focus is not on cheap shortcuts that risk quality, but working smarter by leveraging techniques like Critical Function Analysis and digital prototyping to eliminate waste before a single block of metal is ever cut. Let’s dive in.

What is Metal Rapid Prototyping and How Does It Define Modern Manufacturing?

Metal rapid prototyping is a method that uses advanced manufacturing technologies, such as CNC machining and 3D printing, to quickly produce metal part prototypes. It not only shortens development time but also allows engineers to test and modify designs early on, reducing errors in later stages. According to industry standards, the definition of rapid prototyping focuses on iteration speed and precision, making it a core element of product development.

In the context of technological innovation, metal rapid prototyping is driving manufacturing toward digital transformation.It is worth noting that the metal rapid prototyping process typically includes design, machining, and testing phases, ensuring parts meet strict specifications. More details can be found in resources like this in-depth article on metal rapid prototyping, which explains definitions, types, and online quoting methods.

- Core Advantages: Rapid prototyping can drastically reduce design iteration cycles from weeks to days, especially suited for high-complexity parts.

- Industry Impact: As the technology universal, more businesses are adopting it to maintain competitiveness.

What Are the Cost Factors of Rapid Prototyping and How to Optimize the Budget?

Rapid prototyping cost is a key concern for many businesses, influenced by materials, machining time, complexity, and volume. Typically, metal prototypes are more expensive than plastic ones, but due to their durability, they may be more economical in the long run. Optimizing the budget hinges on early planning and technology choices, such as testing with small-batch prototypes before mass production to avoid waste.

- Cost Breakdown: Materials account for 30%, machine time for 40%, and post-processing for 30%. Companies can reduce machining time through standardized designs and by understanding and mitigating factors that affect machining efficiency, such as tool wear and heat generation.

- Optimization Strategies: Adopting modular designs or shared machining resources, like cloud manufacturing platforms, can effectively control rapid prototyping cost.According to certifications like ISO 9001, optimization should also focus on quality control to avoid rework costs. More cost-saving tips can be found on the rapid prototyping services page, which offers detailed guidance.

Understanding the Exponential Cost-Tolerance Relationship

The relationship between tolerance tightness and cost is not linear; it’s exponential. As tolerances become stricter, the required manufacturing effort surges. This involves:Using more precise, often slower, machining centers.Implementing longer and more complex inspection cycles, sometimes requiring specialized coordinate measuring machines (CMM).

A higher likelihood of parts falling outside the tolerance band, leading to increased scrap rates.Research from institutions like the National Institute of Standards and Technology (NIST) highlights that the cost of maintaining ultra-tight tolerances can far exceed the base material cost of the part itself.

Implement a “Critical Function Analysis” to Cut Costs Intelligently

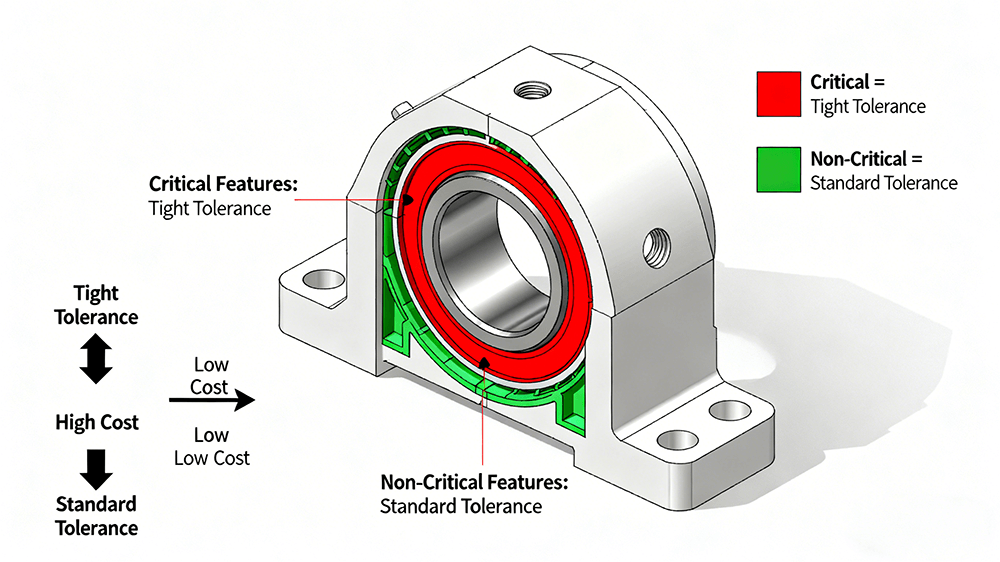

Figure 2: Critical Function Analysis helps identify where to apply tight tolerances (red) and where standard tolerances (green) are sufficient, optimizing rapid prototyping costs.

The most powerful cost-saving lever is often your tolerance specification. The key isn’t to apply loose tolerances everywhere, but to be strategically strict. This is where Critical Function Analysis becomes your secret weapon.

Instead of applying blanket ±0.05 mm tolerances across your entire part, work with a qualified manufacturing partner to dissect the design. For example, in a recent project with a medical device startup, a Critical Function Analysis was performed on a complex surgical tool housing.

The Result? We identified that only three bore diameters and two mounting surfaces were truly critical for device function and sterility. By rationally relaxing tolerances on over a dozen other non-critical features (like internal ribbing and external cosmetic surfaces), we reduced the client’s prototyping cost by 35% and machining time by 28% — without any compromise to the product’s performance or safety. This collaborative analysis is a core part of our DFM (Design for Manufacturability) process, which you can learn more in a dedicated Case Study: How to control CNC rapid prototyping costs factors and solutions.

This strategy requires a partner with a rigorous quality culture (like ISO 9001:2015 and ISO 13485 certified processes) to ensure that relaxation is done scientifically, not arbitrarily. It’s not about cutting corners; it’s about cutting costs smartly.

Partner Expertise is Key

Successfully implementing this strategy hinges on partnering with a manufacturer possessing a rigorous quality culture, often evidenced by certifications like ISO 9001:2015 and IATF 16949. Their expertise ensures that tolerance relaxation is scientifically managed, safeguarding product quality while unlocking significant cost optimization potential, potentially up to 40% per part.

Stop Costly Late-Stage Changes with Digital Prototyping

Think of rapid prototyping not as an expense, but as the cheapest insurance policy you’ll ever buy. The single biggest budget killer in product development is discovering a critical flaw after you’ve already committed to production tooling.

Fail Fast, Learn Cheap: The Power of Early Validation

Think of rapid prototyping not as an expense, but as the cheapest insurance policy you’ll ever buy. The goal is to accelerate iteration — to test multiple design variations quickly and uncover flaws when they are cheapest to fix.

Consider this real-world example: In one instance, an automotive client validate a new sensor bracket. The first prototype revealed an unanticipated vibration issue. Because we caught it early, a simple design tweak cost less than 500. Had it be end is covered during mass production, the delays and mold modifications would have exceeded 50,000.

This case highlights the core benefit: a thorough rapid prototyping process significantly de-risks mass production. But the advantages go beyond catching single errors.

The Seamless Path to Production

The true ROI is realized when your prototyping partner can also be your production partner. Selecting a manufacturer that offers an integrated service — from rapid prototyping to high-volume production — ensures a seamless transition.

- Knowledge Transfer is Built-In: The lessons learned during the prototyping phase are directly incorporated into the production process. The team that machined your prototypes already understands the design nuances, potential pitfalls, and critical tolerances.

- Eliminate Costly ECOs: This continuity minimizes disruptions and virtually eliminates those expensive, late-stage Engineering Change Orders (ECOs). The upfront investment in a comprehensive prototyping process with the right partner routinely delivers a return of 10x or more by avoiding these downstream crises.

It’s not just about making a prototype; it’s about building a smoother, faster, and more predictable path to a successful product launch.

What Constitutes True Value? A Deeper Look at Manufacturing Partner Selection Criteria

While unit price is a tangible starting point, selecting a manufacturing partner on cost alone is a short-term strategy that can compromise long-term project success. A more strategic approach evaluates the total cost of ownership (TCO), which encompasses factors like lead time, quality consistency, engineering support, and risk mitigation. These elements, often overlooked in a simple price comparison, ultimately determine the final project’s budget, timeline, and quality.

Key Pillars of a High-Value Manufacturing Partnership

A strategic partnership is built on foundational capabilities that deliver value beyond the initial quote. Decision-makers should prioritize partners who excel in the following areas:

- Comprehensive Technical Capabilities:A supplier offering a wide range of services—such as CNC machining, injection molding, and sheet metal fabrication—can provide unbiased advice on the most suitable and cost-effective technology for a project. This avoids the limitation of being forced into a single process that may not be optimal.

- Industry-Specific Expertise and Certifications:Relevant certifications are a proxy for deep expertise and a commitment to quality. For instance, ISO 13485 for medical devices and AS9100Dfor aerospace demonstrate a certified system designed to meet the rigorous standards of these industries, thereby reducing compliance risk.

How Do Advanced Technologies Like 5-Axis Machining Add Value Beyond Cost?

While advanced manufacturing technologies may come with a higher hourly rate, the value they deliver, especially for complex projects, often justifies the investment.

1. Reduced Lead Times and Enhanced Accuracy

Technologies like simultaneous 5-axis CNC machining allow for the completion of complex geometries—such as deep cavities, undercuts, and contoured surfaces—in a single setup. This eliminates the errors and time associated with multiple re-fixturing operations, significantly compressing the overall production timeline and improving part accuracy.

2. Unlocking Design Innovation

These capabilities provide engineers with greater design freedom, enabling the creation of lightweight, high-strength structures (like lattices) or integrated components that would be impossible or prohibitively expensive to produce using traditional 3-axis machining.

3. Superior Part Consistency

By machining a part in a single fixture, the geometric relationship between features is maintained with exceptional precision. This consistency is crucial for high-performance applications in sectors like aerospace and automotive, ensuring reliability in the final assembly.

Conclusion

Achieving meaningful cost optimization in precision manufacturing requires a holistic strategy that looks beyond the price tag. It involves a fundamental shift towards intelligent design practices, leveraging technology for validation, embracing sustainable efficiency, and forging strategic partnerships with certified experts. By implementing these research-driven strategies—strategic tolerance design, digital prototyping, sustainable practices, careful partner selection, and leveraging advanced technologies—manufacturers can significantly reduce their rapid prototyping cost and accelerate time-to-market, all while maintaining the highest standards of quality and innovation required in today’s competitive landscape.

FAQs

Q:What is the single biggest cost driver in CNC machining besides material?

A:Part geometry complexity is a major driver. Complex designs require longer programming, more sophisticated machining strategies, and increased machining time, directly impacting cost.

Q:Is CNC machining suitable for very low-volume production, even just one part?

A:Absolutely. CNC machining is ideal for low-volume and one-off production because it requires no expensive tooling, unlike injection molding. This makes it perfect for rapid prototyping and custom parts.

Q:How can I be sure my parts will meet the quality requirements for regulated industries like medical or aerospace?

A:Choose a manufacturing partner with relevant certifications. ISO 13485 for medical devices and AS9100D for aerospace demonstrate a certified quality management system designed to meet the rigorous standards of these industries.

Q:For rapid prototyping, which is generally less expensive to machine, aluminum or steel?

A:Aluminum is typically less expensive. It machines faster, causes less tool wear, and the raw material is generally cheaper than most steels, making it a popular choice for functional prototypes.

Q:How does a good rapid prototyping process help with the transition to mass production?

A:A thorough rapid prototyping process validates the design, identifies potential manufacturing issues, and allows for optimization for mass production. Working with a partner that offers both prototyping and production services ensures a smooth transition, as the production team is already familiar with the design and its requirements.

Author Bio

Jason Lee is the Director of Engineering at JS Precision which is the team leverages its ISO 9001:2015 and AS9100D certified processes to deliver parts that consistently meet the highest standards of quality and precision. Jason has over 15 years of experience in precision CNC machining and additive manufacturing, he has helped hundreds of engineers and innovators from startups to Fortune 500 companies navigate the complexities of rapid prototyping and low-volume production.

Have a prototyping challenge? Jason and his team are here to help. Contact them Today for a free, no-obligation project review and DFM analysis. Let’s turn your concept into a cost-effective reality.