Today fast manufacturing has made efficiency, accuracy, and floor space utilization important parameters. One of the main novelties that has a great impact on the flange production sector is the compact, high-precision machinery, which has been widely adopted. The small CNC gantry drilling machine takes the lead in this transition as it is the powerful, space-saving solution that is now setting the productivity standards in modern workshops.

What is a Small CNC Gantry Drilling Machine?

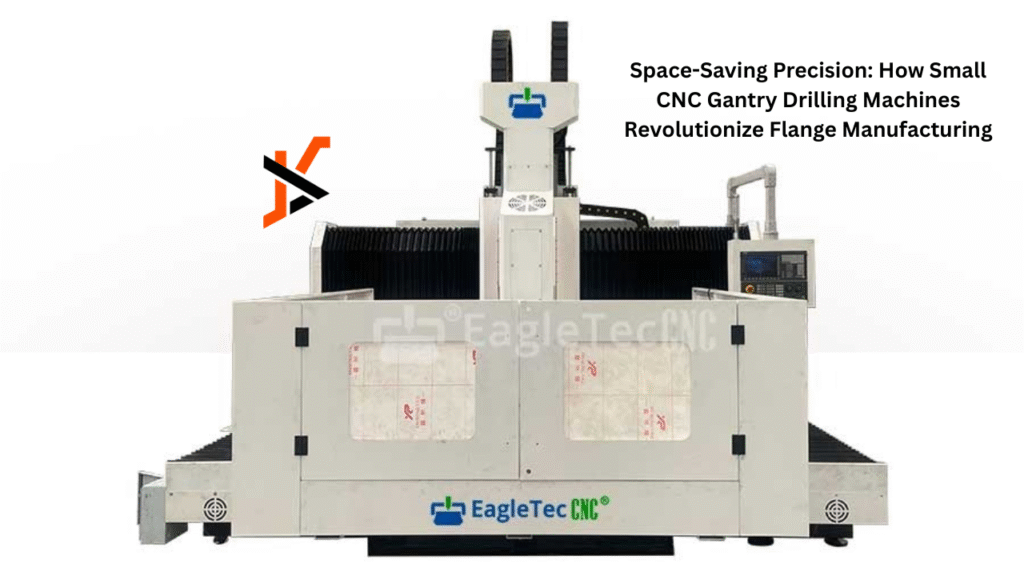

A small CNC gantry drilling machine is modern computer-controlled drilling equipment that is capable of doing heavy-duty operations on metal parts like flanges; nevertheless, it occupies less space than the traditional gantry machines. CNC means Computer Numerical Control, which implies that the drilling operation is automated, and thus, high accuracy and repeatability are ensured.

The traditional gantry machines need a huge area and heavy infrastructure, whereas the small CNC gantry type, in considerably less space, can perform the same. Thus, it is by no means a bad choice for small to medium-sized fabrication shops or manufacturers looking to optimize their space while still having accurate results.

The Role of CNC Drilling in Flange Manufacturing

Flanges are parts of the utmost importance across various industries like oil & gas, petrochemical, energy, and building construction. They are used as the interconnections for pipes, valves, and other parts. The drilling of flange bolt holes with the highest precision is an extremely significant step in the creation of leak-proof, safe, and dependable connections.

Traditional manual drilling methods or larger machines often bring in inconsistencies, particularly when working with large batches or custom orders. A small CNC gantry drilling machine provides the solution to these problems by delivering:

- Automated hole positioning

- Consistent drilling depth

- High repeatability

- Reduced human error

Key Advantages of Small CNC Gantry Drilling Machines

1. Space Optimization

One of the best characteristics of a small CNC gantry drilling machine is its small footprint. This gives manufacturers with minimal floor space a big advantage. These machines can be seamlessly incorporated into current workflows without the need for major reorganization or moving around.

By virtue of space, manufacturers can install more machines or workstations in the same area. Which creates the same amount of output without the need for an expansion of facilities, thus contributing to the overall production increase.

2. Cost-Effective Operation

The size of the machine has a direct effect on the energy consumption during operation; hence, smaller machines’ electricity bills are lower. Besides, maintenance and servicing on such machines is less demanding as compared to the large CNC machines.

Besides, the purchase price of the small CNC gantry drilling machine is usually lower, which means that even the smallest manufacturing companies or start-ups can afford to invest in the latest technology.

3. Precision Engineering

These machines are small but still deliver precision performance. They can be controlled by high-end CNC and will be able to drill with very slight deviation, making it possible to meet the production tolerances that are critical in flange manufacturing.

Thus, it guarantees that the alignment of the bolt holes is correctly done and the amount of waste and rework is reduced, and the quality of the product is made more reliable.

4. High-Speed Production

The workflow in flange component manufacturing is sped up a lot due to the use of CNC technology, which allows for the processing of the pieces to be done in a very short time. The machine can be set up to drill multiple holes at once with just a few manual inputs and is not limited to carbon steel. It can also be used with stainless steel or any other metal used in the industry.

This application of efficiency is mainly in high-production environments where consistency and speed are of utmost importance.

5. Versatility in Application

A miniature CNC gantry drilling equipment can process different flange sizes and materials. The adjustable heads for drilling and the customizable CNC programs enable the operators to quickly switch over to different workpieces without having to undergo any lengthy retooling that consumes time.

This ease of operation is crucial for manufacturers who get custom orders or have a variety of client requirements.

Use Cases: Real-World Applications

Flange manufacturers around the world are integrating small CNC gantry drilling machines into their operations for:

- Custom flange production – Drilling patterns can be programmed for any bolt configuration.

- Batch production – Quickly producing hundreds or thousands of identical flanges.

- Prototype development – Creating precision prototypes for testing and validation.

- On-demand manufacturing – Swift production process without extensive setting up and manual labor involved.

How They Improve Workflow Efficiency

Classic flange drilling process utilized a sequence of operations wherein each of them manual measuring, positioning and drilling was prone to human error. CNC gantry machines do away with this problem by incorporating CAD/CAM software and automating the process.

Operators can upload a digital design, align the workpiece, and let the machine take over. This improves:

- Turnaround time

- Workforce efficiency

- Overall production capacity

Since one operator can manage multiple machines or oversee several automated tasks simultaneously, labor costs are also reduced.

Sustainability Benefits

With industries transitioning to eco-friendly operations, the small CNC gantry drilling machine is here to stay, with its environmental advantages also:

- Motors and systems that consume less energy

- Precision results in less material waste

- Compact design leading to a smaller environmental footprint

The firms targeting ISO 14001 or any other environmental certifications can reap the benefits by using the machine in their production lines.

Choosing the Right Machine

When a small CNC gantry drilling machine is to be selected, the following factors should be considered by manufacturers:

Drilling capacity: It is necessary to align the machine capabilities with the dimensions and thickness of the flanges made.

Spindle power and speed: The influence of these parameters is such that they determine the range of materials the machine can work with.

Software compatibility: The device should be able to handle CAD/CAM file formats that are the most common ones used.

After-sales support: The availability of constant and reliable technical support is a primary factor for the machine’s performance and output.

Additionally, one more thing that should be kept in mind is that the ROI must be calculated with a long-term perspective. By getting the right device, the investment can be compensated by getting rid of errors, fast forwarding the manufacturing process, and decreasing the cost.

Final Thoughts

Flange manufacturing process evolution relies a lot on innovations, and a small CNC gantry drilling machine is a perfect case to show how little technology can generate big advantages. The small CNC gantry drilling machines make it possible for companies of all sizes to enhance accuracy, minimize expenses, and fine-tune their processes without the need for large factory spaces.

The current trend points to the gradual extinction of bulky equipment due to the demand for smarter and more cost-effective manufacturing solutions. Thus, the movement of compact CNC machines is no longer an option but rather a strategic necessity. Whether you operate a small workshop or run a large industrial plant, the small CNC gantry drilling machine investment may well be the secret to your competitiveness in the continuously changing flange manufacturing arena.