In pharmaceutical manufacturing, efficacy, precision, and quality are of the utmost importance, especially within the manufacture of medicines. Production lines for tablets and pills that operate at high speed require advanced hardware to maintain their efficiency and accuracy. One such critical equipment is a pill counter machine, which ensures the right counting and dispensing of pills for sale.

Understanding the importance of pill counting machines in high-speed production lines, the benefits accrued by these machines by the pharmaceutical manufacturers, and the reason why more and more pharmaceutical equipment suppliers are including these machines in their offerings is the focus of this article.

The Role Pill Counter Machines Play In Modern Automated Production Systems

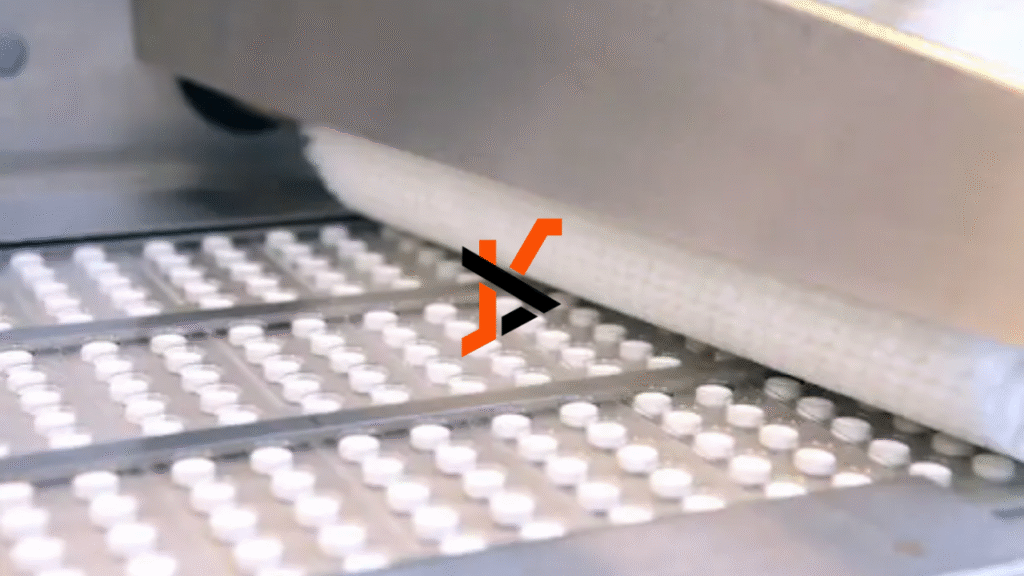

Pill counter machines aid in the automation of counting pills during the final stages of packaging. When it comes to high-speed production lines where hundreds of thousands of pills are produced every minute, they cannot be counted manually. Manual counting is inefficient and error-prone. A pill counter machine mitigates this risk by ensuring the pill counts are highly accurate and consistent.

To meet regulatory demands, pharmaceutical manufacturers have to follow strict guidelines for quality control. Each bottle or package of pills must be counted accurately to guarantee that the consumer receives the correct dosage. For companies that work within the boundaries of highly regulated markets such as pharmaceuticals, the accuracy and dependability of pill counting machines is a must.

Aside from regulatory restrictions, pill counter machines enable manufacturers to enhance productivity. These machines work at breakneck speeds, which helps manufacturers meet market demands without losing accuracy or reliability.

How Machines Industry Pill Counter Work

There are various methods and techniques that allow for the rapid and accurate counting of pills, and they include vibration plates, high-speed conveyors, and optical sensors. Typically, counting machines feed the pills into the counting chamber where they will be counted automatically sorted and put into different packaging containers.

As the pills travel through the machine, optical sensors capture the size and shape of every pill, allowing the system to count pills with utmost precision. This technology is useful in eliminating human error, something highly needed in the pharmaceutical sector where precise dosing is critical. Advanced models may also incorporate batch counting, weight checking, and automatic rejection of defective pills, guaranteeing utmost accuracy and quality control.

Pill counting machines are also able to integrate easily into high-speed production lines alongside other automated machines. These types of machines are needed, whether in bulk tablet production or capsule filling, to ensure that the end product is uniform and available for immediate shipment.

The Responsibilities of Pill Counter Machines in Quality Control

While in high-speed production lines, ensuring the product’s quality is a top concern. One of the primary responsibilities of a pill counter machine is to verify that every package contains the exact number of pills as indicated by the manufacturer. Not only is this essential for regulatory guidelines, but it is also imperative for customer satisfaction.

By completely mechanical automation of the counting process, pill counter machines eliminate human error. It is no secret that regardless of how seasoned human operators are, there is always room for error in a speed-centric production setting. With a pill counter machine, every pack is guaranteed to have the right quantity of pills, reducing chances of underfilling or overfilling containers, compliance issues, and customer complaints.

Furthermore, many modern pill counter machines have additional quality control features. For example, some machines weigh the pills to make sure no pill is heavier than the other. Other machines may use metal detection methods to verify that no harmful substances are present. These amazing initiatives ensure that the market is not flooded with substandard quality goods.

Increasing Speed and Efficiency in Great Volume Production Lines

Pill counter machines are able to achieve accurate results fast. In a high-speed production environment, efficiency is a must, and these machines are built for speed.

Counter devices can accurately segregate thousands of pills in a minute making it efficient for manufacturers to keep up with market’s demand. Performing this function at an ultra high pace increases the output and optimizes production time to improve the delivery punctuality.

Apart from speed, a counter machine requires minimal maintenance. Self-service options and a user-friendly interface reduces the supervision requirement further increasing overall process improvement.

Automation and increased speed through the use of counter machines help manufacturers improve the quality and accuracy of their medicational products.

Why Pharmaceutical Equipment Suppliers Recommend Pill Counter Machines

Suppliers assist manufacturers with the required equipment for modern production lines and tackle the challenge of automation and precision. They have increasingly recognized the usefulness of pill counter machines and efficiency multifold productivity.

Incorporating pill counter machines into their offerings enables tablet press machine manufacturers and pharmaceutical equipment suppliers to assist clients with an automated production line. Through these machines, operations are made easier, product uniformity is enhanced, and all regulatory requirements are met. Suppliers also face the added responsibility of providing qualitatively superior counter machines to enable their clients to retain competitiveness in the market, Jordanek (2022) argues.

Allowing pharmaceutical manufacturers to make the best decision for their specific needs, pill counter machines are also highly customizable. Regardless of whether the manufacturers are producing tablets with different shapes and sizes or capsules with special features, the machines can be configured to suit the product. Such flexibility makes them indispensable for pharmaceutical equipment suppliers to include in their products, Jerden (2022) states.

The Future of Pill Counter Machines in Pharmaceutical Manufacturing

Pill counter machines will be sure to become even more important in the future of pharmaceutical manufacturing as the industry continues growing and faces the new challenge of needing higher outputs in shorter time frames. Keeping up with increasing vertical integration will also incorporate the need for more advanced and efficient production technologies.

The technology behind pill counter machines is advancing week by week, and the future looks even more promising. Future iterations may include AI and machine learning to improve the accuracy and speed of the counting process. With IoT integrated, manufacturers would be able to monitor their production lines in real time, gaining insight on the performance of pill counter machines and enabling predictive maintenance to save time.

As pharmaceutical equipment suppliers keep innovating, the capabilities of pill counter machines will get wider, offering even more features to help them deal with modern challenges.

Conclusion

Pill counter machines are an integral element of high-speed production lines in the pharmaceutical industry. They save valuable time while increasing the requirements for accuracy, speed, and efficiency when producing large quantities of tablets and pills. These machines assist pharmaceutical manufacturers in meeting compliance with regulatory standards, enhancing product quality, and optimizing production processes.

In meeting the needs of the pharmaceutical industry, suppliers of pharmaceutical equipment should offer powerful pill counter machines. These instruments guarantee an effective answer to the problems associated with high-speed production while helping manufacturers meet the demand in the market without compromising on quality.

Producing tablets and pills will also require advanced technology in the future. This shows that pill counter machines will be fundamental in the evolution of the pharmaceutical industry.