What this article covers

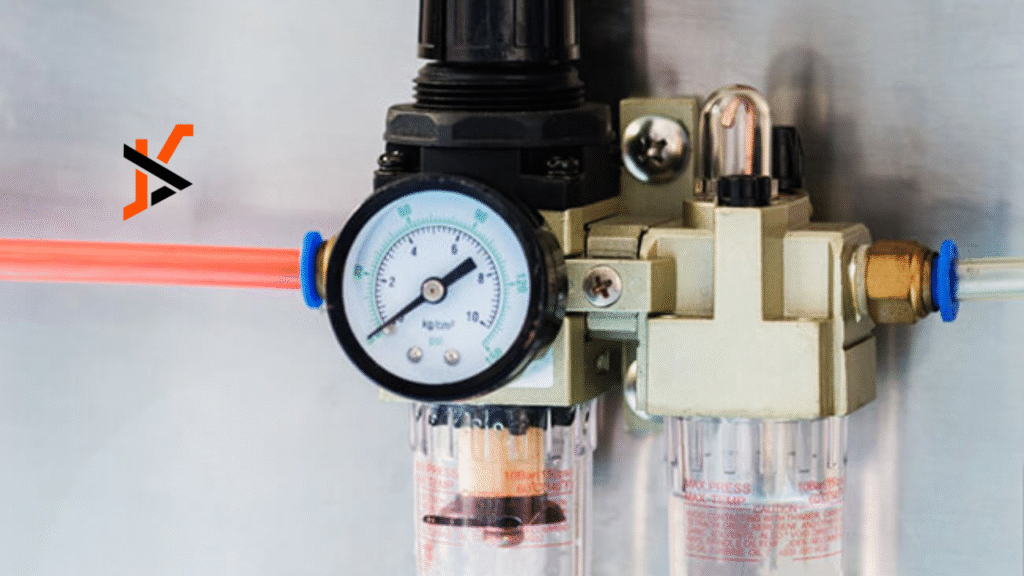

This article is all about the common issues with the proportional pressure regulator and how to fix them in simple ways. This way, anyone can safely try solving them on their own.

Why a regulator malfunctions

A regulator malfunctions when:

- It’s blocked for any reason,

- Set to the wrong settings,

- It contains leakage, or

- Doesn’t have enough power to perform.

If some of these happen, then there is a high chance that the regulator will malfunction. Let’s understand this with an easy example. You can think about whether a tap is blocked due to some reason that results in changing or completely blocking the air flow.

Easy checklist to start

- Look for air leaks. Listen for hissing near fittings and pipes.

- Check the power source. Make sure the controller gets the right voltage.

- Verify settings. Ensure the set point matches what your machine needs.

- Inspect the filters. Dirty filters reduce flow and cause poor control.

Common problem: no output or weak flow

What happens: the device gives little or no air.

Simple test: open the downstream valve and listen. If no air moves, the unit may block.

Quick fixes:

- Replace or clean the filter.

- Check and clear any dirt particles in the valve.

- Confirm the incoming supply pressure is enough.

If the unit still fails, call a technician.

Problem: unstable or jumpy pressure

What happens: pressure moves up and down without reason.

Simple test: watch the gauge while you change the load slowly.

Quick fixes:

- Tighten loose fittings. Small leaks can make the pressure jump.

- Check for water or oil in the line and drain it.

- Adjust the control gain carefully if the unit allows it.

For electronic models, such as an electronic proportional pressure regulator, check the control signal and wiring.

Problem: slow response

What happens: the regulator takes too long to reach the set pressure.

Simple test: apply a sudden change in demand and time the response.

Quick fixes:

- Replace clogged filters.

- Verify the supply reservoir has enough volume.

- Inspect tubing for long runs or small diameters that slow flow.

This issue can also arise in an electro pneumatic regulator when the pneumatic parts lag behind the electronic command.

Problem: wrong output pressure

What happens: pressure sits at a different value than the set point.

Simple test: compare the set value to the gauge reading.

Quick fixes:

- Calibrate the sensor or gauge.

- Check if the set point reference is correct.

- Replace worn internal parts like seals.

When to call a pro

If you find burned electronics, internal damage, or repeated failure, stop right there and call a professional technician. Because if you try to replace the parts without the right tools, he problem might get worse.

Simple safety steps

- Turn off the power and bleed pressure before opening the unit.

- Always wear safety gloves and safety glasses.

- Follow the instructions set by the market.

Avoid problems before they start

- Use clean, dry air with good filters.

- Keep up with routine checks and simple cleaning.

- Use the right size valves and tubing.

- Store spare filters and seals for quick swaps.

Final tip: keep a small log

Write down the problem, what you checked, and what you changed. Over time, the notes will help you spot patterns and fix things faster.

Remember: a good routine keeps systems healthier. A simple check every week saves hours later. If your proportional pressure regulator still misbehaves after these steps, log what you tried, take photos, and share them with a service team. Clear notes speed repairs and cut downtime, and stay safe while working today.