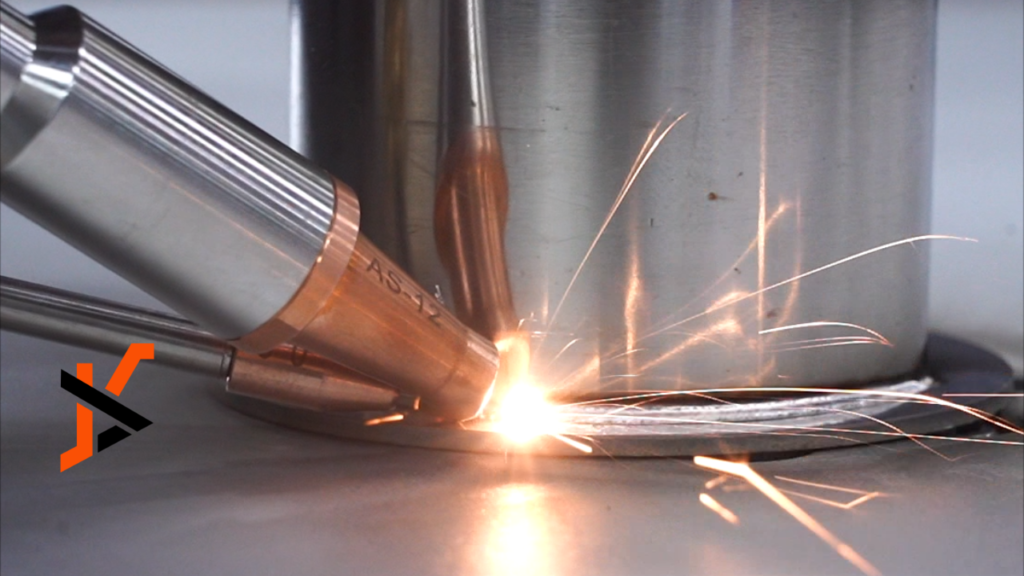

Laser welding and MIG welding are different methods of enrolling in metal portions together. They are utilized in industries like manufacturing, automotive, and construction. Laser welding uses an effective mild beam to soften and fuse steel elements. It’s like the usage of a targeted flashlight to enroll in things. It uses a wire electrode.

The electrode melts. It shapes a bond among the metals. It’s a chunk like a warm glue gun but with steel rather than glue. Laser welding is precise and can weld thin materials. However, it requires expensive equipment and may not work well with reflective materials. MIG welding is affordable and versatile, but it may produce more spatter.

Understanding Laser Welding

Laser welding is a manner to sign up for metals collectively quickly. It makes use of an effective beam of mild to soften metals. This melted steel paperwork created a robust bond among them. The mild beam could be very targeted and specific. It’s like the usage of a first-rate robust flashlight to weld.

It’s incredible to become a member of skinny or sensitive materials. This technique can create precise welds. Engineers and producers frequently select laser welding for its accuracy. It’s essential to put on protective equipment while using lasers.

Understanding MIG Welding

MIG welding joins metal portions collectively using strength and cord. Choose one cord that melts to create a bond among the metals, like using a warm glue gun with steel. This approach is not unusual in the construction and car industries. It’s flexible and may be used on diverse metals.

Beginners can research MIG welding strategies exceptionally quickly. Welding machines for MIG welding are extensively available. MIG welding can produce sturdy andm sturdy joints. It’s crucial to observe protection precautions while welding with MIG.

Precision and Accuracy

Precision way of doing something cautiously and appropriately without mistakes. Accuracy

is how near a size is to its proper value. In many activities, precision, and accuracy cross hand in hand. For example, in archery, hitting the goal middle indicates each. Precision is consistent in doing obligations correctly.

Accuracy specializes in getting the proper result every time. Precision and accuracy are essential in many fields. Science experiments require particular measurements and correct observations. Engineers want precision when designing machines and buildings. Even in sports activities like basketball, taking pictures with precision wins games. Practice allows enhanced precision and accuracy over time.

Cost and Affordability

Cost refers to how much cash something costs to buy. Affordability means whether something is reasonably priced or luxurious. When shopping for things, it’s critical not to forget their value. Some objects can be too luxurious for your budget. Affordability allows you to decide what you may and can’t buy. Different elements affect the value of products and services. These consist of substances used, labor, and manufacturing methods.

Comparing charges can help locate the most low-cost option. Sometimes, inexpensive objects might not be of proper quality. Quality frequently correlates with better charges for merchandise and services. Understanding the value and affordability allows for budgeting wisely. Saving cash for critical matters is a clever decision. Always do not forget the long-term charges of purchases.

Application and Suitability

Application refers to how something is utilized in one-of-a-kind situations. Suitability if

something is proper or suitable for a task. Understanding utility and suitability facilitates making sensible choices. Different gear have unique packages wherein they work best. Suitability is set to match the proper device for the job. For example, a hammer is appropriate for pounding nails. But it’s now no longer suitable for slicing wood like a saw.

Assessing suitability guarantees responsibilities are finished effectively and safely. In cooking, deciding on the proper substances is essential for suitability. Application and suitability move hand in hand in problem-solving. Engineers recollect utility and suitability while designing new technologies.

Assessing the suitability of alternatives before deciding is crucial. Matching talents to

responsibilities demonstrates the significance of suitability. Experimenting facilitates recognizing the utility and suitability of various tools.

Conclusion

In conclusion, each laser welding and MIG welding has its strengths and weaknesses. Laser welding provides precision and accuracy. It’s perfect for sensitive materials. But it can be expensive and limited by material type. So, MIG welding is affordable. It is versatile and suitable for many metals. Yet, it may lack precision and produce more spatter.

Choosing among them depends on unique project needs. Consider factors like budget. Material is important, too—the desired outcome matters. Understanding variations in utility is fundamental. The suitability of each technique matters. It’s crucial for making the proper decision. Experimentation and cautious assessment can result in a successful welding project.